All categories

29

2018

-

09

Precautions for Replacing New Parts in Agricultural Machinery

Author:

Some operators believe that repairing agricultural machinery and replacing parts is very simple

Some operators believe that repairing agricultural machinery and replacing parts is very simple, just installing the new parts will do. However, this is not the case. If the new parts are not assembled properly, it can lead to a decrease in the power of the agricultural machinery, increased fuel consumption, and difficulty in starting. In severe cases, it can damage the machine. Therefore, when purchasing replacement parts, the following points should be noted:

1. When purchasing new parts, attention must be paid to the quality of the parts. Do not buy inferior products; carefully check for rust spots, cracks, deformations, and other defects, and ensure that the surface dimensions meet the requirements.

2. Before assembly, the anti-rust coating on the surface of the new parts should be completely removed. This is especially important for precision components to avoid potential safety hazards.

3. Certain matching parts should be replaced in pairs. For example, when replacing gears, do not only replace the one that is more severely worn; when replacing a double-row sleeve roller chain in a transmission box, both the driving and driven sprockets should be replaced in pairs; when replacing a cylinder sleeve, the piston and piston rings should also be replaced simultaneously.

4. Standard parts of the same model are not interchangeable with oversized parts. Manufacturers produce oversized spare parts for users to choose from during repairs. Therefore, when selecting parts, it is essential to determine whether the purchased part is a standard part or an oversized part. For instance, a shaft neck can only be matched with standard crankshaft bearings; otherwise, if machining is required for bearing scraping, it will take a lot of time and cannot guarantee repair quality while significantly reducing the lifespan of the parts.

5. When replacing new parts, the model of the new part must be exactly the same as that of the old part. Some operators do not pay attention to the specifications of the original fuel injector when replacing it and mistakenly buy a needle valve component, which often leads to difficulties in starting at best and a jammed fuel injector at worst.

6. Attention must be paid to orientation during installation. Some parts have directional characteristics; if installed incorrectly, it can lead to starting difficulties or even damage to components.

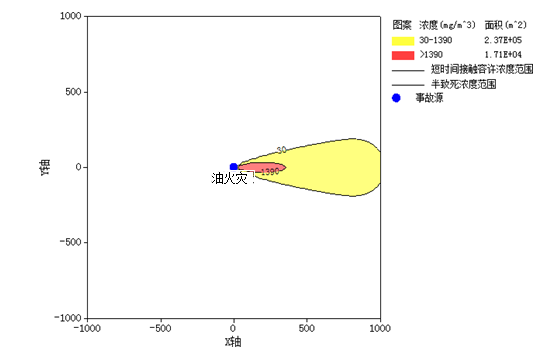

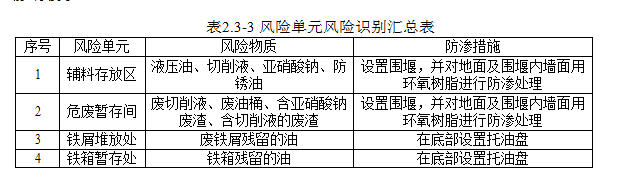

3.4.2 Diffusion Pathways of Risk Substances in Water Environment Under abnormal circumstances

2019-11-20

There are risks of leakage and fire during the transportation of raw materials such as guide rail oil

2019-11-20