All categories

20

2019

-

11

Risk Assessment Report on Sudden Environmental Incidents of Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. (3)

Author:

3.4.2 Diffusion Pathways of Risk Substances in Water Environment Under abnormal circumstances

3.4.2 Water environment risk substance diffusion pathways:

Under abnormal circumstances, hazardous chemicals leaking may flow along the surface into lower-lying ditches, even overflowing into the Ganzi Creek, contaminating surface water bodies; the soil through which wastewater containing hazardous chemicals is discharged will be contaminated to varying degrees.

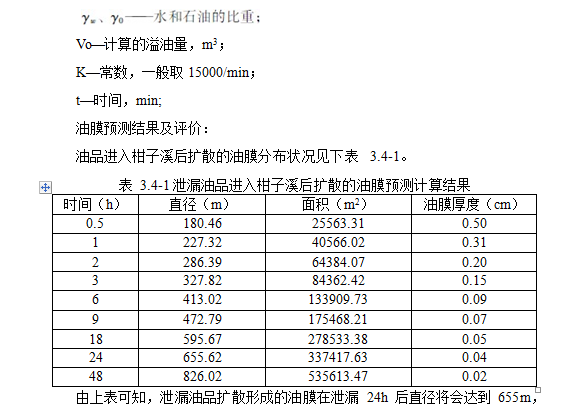

The oil film (or oil slick) formed by sudden accident leaks can also be broken and emulsified into water under the action of waves, and can be calculated according to the convection diffusion equation, just like the oily wastewater discharged from accidents. Its basic equation is:

If not handled in a timely manner, it will have a serious impact on the aquatic ecology in the area covered by the oil film.

In cases of no wind or waves, oil barriers are generally used to prevent the spread of leaked oil, while oil recovery boats and absorbent mats are used for treatment. When appropriate measures are taken by enterprises, it can effectively prevent the impact of leaked oil on the water environment.

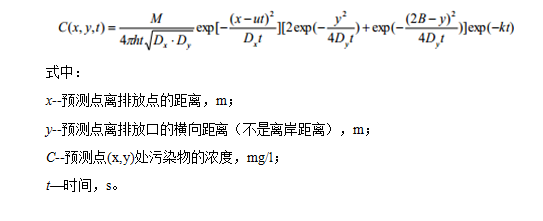

Under windy (wavy) conditions, the oil film formed by sudden accident leaks will also be broken and emulsified into water under the action of waves. It can be evaluated using the concentration field prediction formula for accidental discharges along large rivers recommended in the "China Environmental Impact Assessment Training Textbook", namely:

h--average water depth of the river, m; B--width of the river, m;

Dx--longitudinal mixing (dispersion) coefficient of the river, m2/s; Dy--transverse mixing (dispersion) coefficient of the river, m2/s; M—instantaneous accident discharge amount, g;

u--flow velocity of the river, m/s; π--pi;

k—degradation coefficient, s-1. Prediction results and evaluation:

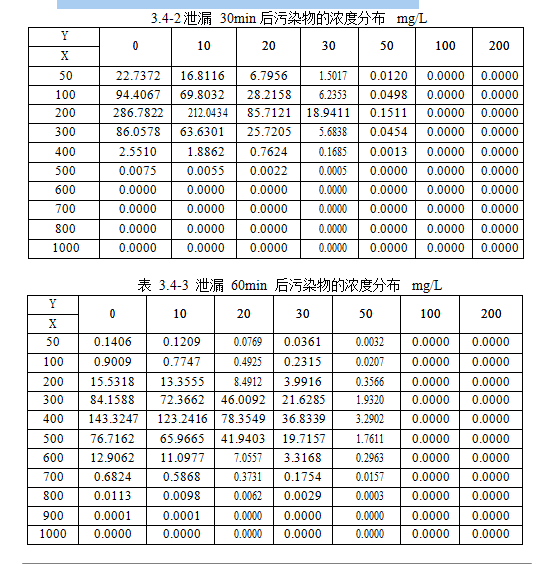

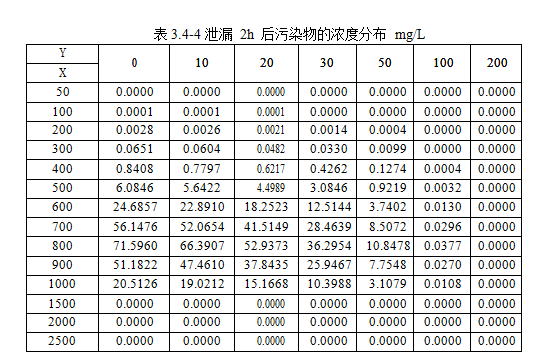

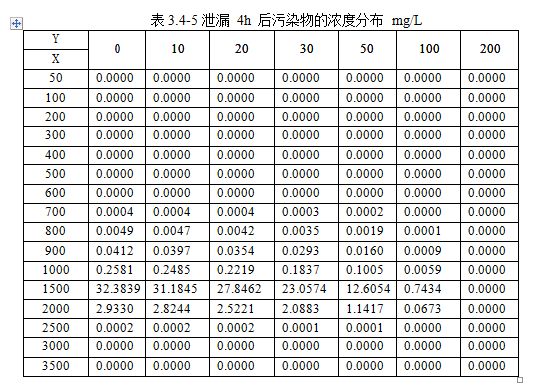

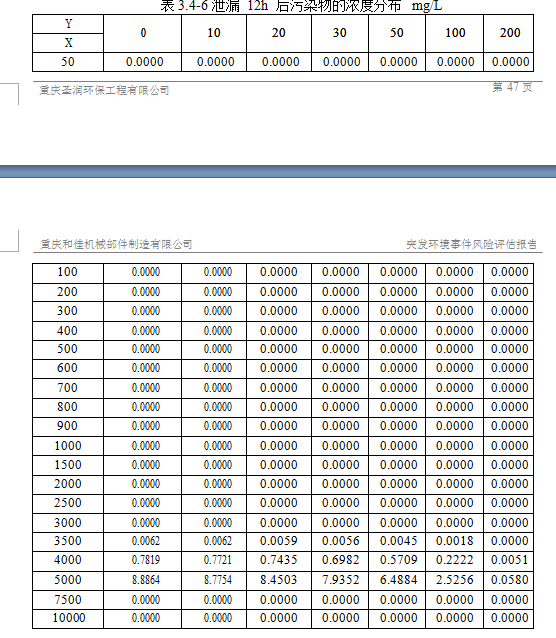

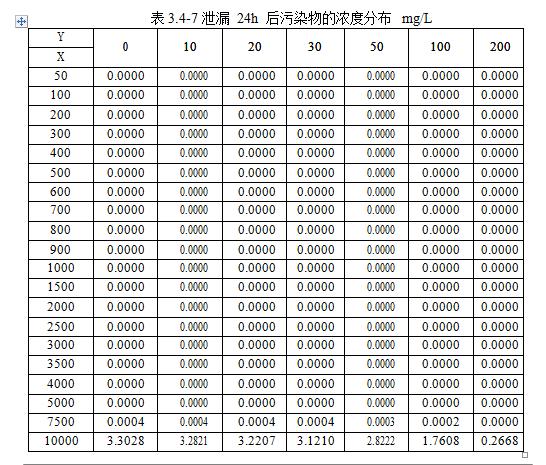

The pollution prediction situation formed at different times after leakage is shown in Table 3.4-2~3.4-7.

From the above table, it can be seen that if there is an oil leak during the oil delivery process in enterprises, the leaked oil will float on the water surface forming an oil pollution belt and will pollute downstream over time. According to predictions, at a water level of 175m, after 1 hour of leakage, its pollution belt will extend within a range of 1km downstream; after 4 hours of leakage, the pollution belt will extend to 2km downstream; after 24 hours of leakage, the pollution belt will reach 10km downstream. Meanwhile, the concentration of pollutants formed by leaked oil far exceeds environmental quality standards and will have a certain impact on the aquatic ecological environment in the region.

3.5 Analysis of consequences of sudden environmental events

3.5.1 Analysis of consequences of leakage accidents

(1) Analysis of consequences of oil leakage in auxiliary material storage area

The ground in the auxiliary material storage area uses epoxy resin for impermeability but does not have a containment dike, which cannot effectively prevent chemical leakage into the external environment.

(2) Analysis of consequences of hazardous chemical leakage in hazardous waste temporary storage room

The ground and inner walls of Hejia Machinery Company's hazardous waste temporary storage room only use ordinary concrete and cannot effectively prevent seepage.

渗。

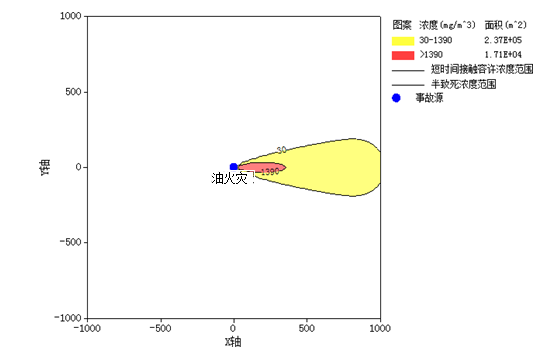

3.5.2 Analysis of consequences of fire and explosion accidents

In case of fire and explosion, it may cause a large amount of wastewater containing chemicals (accident wastewater) to leak out.

The harmful gases such as CO and smoke generated may affect the health of workers and nearby residents.

(1) Accidental leakage of chemical substances:

Chemical substances may enter water through sewage pipelines, potentially causing water quality to exceed standards. If chemical substances directly flow into nearby soil through rainwater ditches, they may damage vegetation.

(2) Harmful gas pollution: In case of fire, a large amount of harmful gases such as CO and smoke generated may also cause poisoning incidents. These directly threaten the health and even lives of workers and nearby residents.

(3) The location where Hejia Machinery Company experienced fire and explosion accidents is mainly in the auxiliary material storage area.

3.5.3 Analysis of consequences of environmental pollution accidents

Hejia Machinery Company's environmental pollution accidents mainly refer to air pollution, surface water pollution, and soil pollution that accompany sudden events.

(1) Air pollution

The materials used by enterprises are flammable. If there are short circuits or damaged wires or electrical appliances burning, it may lead to fires or explosions involving stored oils at Hejia Machinery Company, generating a large amount of harmful gases containing CO and smoke.

(1) CO belongs to gaseous pollutants. Gaseous pollutants emitted from sources can directly pollute the atmosphere or form secondary pollutants through reactions. CO is classified as a primary pollutant.

CO is a toxic gas produced by incomplete combustion of carbon-containing substances; it is colorless, odorless, non-irritating with a specific gravity of 0.967 and is almost insoluble in water. It is an asphyxiating gas that generally does not cause harm due to atmospheric diffusion dilution and oxidation after entering the atmosphere; therefore, it is often undetected when inhaled and is a common pollutant in indoor and outdoor air.

(2) Smoke belongs to particulate pollutants and can be divided into settled dust and suspended dust based on particle size. Settled dust has a particle size greater than 10 microns and can naturally settle due to its weight; its amount per unit area is used as an indicator for evaluating air pollution levels.

The particle size of suspended dust is less than 10 micrometers, and the small particles are light, allowing them to float in the atmosphere for a long time. The floating range extends from several kilometers to tens of kilometers. Therefore, it continuously accumulates in the atmosphere, gradually increasing the level of pollution. Suspended dust is complex, including inorganic and organic substances. Inorganic substances include asbestos, silica, metal materials (mercury, lead, chromium, cadmium, manganese, iron, etc.) and their compounds. Organic substances include various hydrocarbons, especially polycyclic aromatic hydrocarbons and other carbon-hydrogen compounds. Suspended dust is hygroscopic and easily absorbs moisture in the atmosphere, forming condensation nuclei with strong adsorption properties that can adsorb harmful gases and various metal dusts emitted from high-temperature smelting, as well as highly carcinogenic benzo(a)pyrene. Some suspended dust particles also have catalytic effects; for example, iron(III) oxide emitted from steel mills can catalyze sulfur dioxide on its surface to become sulfur trioxide and absorb water to form sulfuric acid. This effect on the surface of suspended dust often increases its toxicity. Therefore, environmental monitoring and health departments regard it as an important indicator for evaluating the impact of air pollution on health.

A large amount of high-temperature waste gas discharged into the ambient air will change the composition of the surrounding atmospheric environment, causing air pollution.

(2) Water pollution

When a fire and explosion accident occurs at Hejia Machinery Company, the firefighting water generated during emergency firefighting becomes accident wastewater, with the main pollutants being COD and petroleum substances. The fire and explosion at Hejia Machinery Company mainly occurred in the auxiliary material storage area. In the worst-case scenario: if the three prevention measures are compromised, chemicals may enter the rainwater drainage system and flow into Ganzi Creek, contaminating the water quality of Ganzi Creek. Especially gasoline has a significant impact on water pollution.

(1) The impact of oil pollutants on water properties

Petroleum pollution in water bodies refers to when oil enters rivers, lakes or groundwater and its concentration exceeds the self-purification capacity of the water body, causing changes in the physical and chemical properties or biological community composition of the water quality and sediment, thereby reducing the usability and functionality of the water body. After entering a water body, petroleum pollutants will form oil films of varying thickness on the water surface. It has been measured that each drop of oil can form an oil film covering 0.25 m² on the water surface; one ton of oil can cover 5×10⁶ m² of water surface. The oil film isolates the water surface from the atmosphere, reducing dissolved oxygen in the water, thus affecting the self-purification ability of the water body and causing sediment to turn black and foul-smelling. Oil films and droplets can also adhere to particles in the water or aquatic organisms, continuously spreading and sinking, expanding their pollution range further and further, destroying the normal ecological environment of the water body. In addition, floating oil on the water surface can also extract chlorinated hydrocarbons dispersed in the water body, such as dichlorodiphenyltrichloroethane (DDT), toxic pesticides like fenitrothion, and polychlorinated biphenyls (PCBs), concentrating these toxins at the surface layer of the water body to harm aquatic organisms.

(2) The impact of oil pollutants on fisheries

The damage caused by petroleum pollution to aquatic environments brings multiple harms to fisheries. Firstly, petroleum pollution can destroy fishing grounds by contaminating fishing nets, aquaculture equipment, and catches; water pollution can directly cause fish deaths, leading to a direct reduction in catch volume. Secondly, it manifests as loss in value; oil pollution can cause fish and shrimp to develop peculiar odors and tastes that cannot be eliminated regardless of processing methods used; thus it can reduce the edible value of aquatic products and severely affect their economic utility. When the oil content in seawater reaches 0.01 mg/L, it can cause fish, shrimp, and shellfish to develop off-flavors within 24 hours. When people consume aquatic products contaminated with carcinogenic substances derived from petroleum hydrocarbons—especially polycyclic aromatic hydrocarbons—these carcinogens can threaten human health and safety through food chain transmission. Additionally, petroleum pollution in water bodies can also cause significant social and economic losses by impacting tourism and recreation.

3) The impact of oil pollutants on aquatic animals

Petroleum pollutants in water bodies mainly accumulate in animals through respiration, feeding, dermal absorption, and food chain transmission. When petroleum pollutant concentrations in water bodies range from 0.01 to 0.10 mg/L, they can have harmful effects on aquatic animals leading to poisoning. The toxicity of petroleum pollutants to aquatic animals increases sequentially from fish to mollusks to echinoderms to crustaceans. Marine larvae are particularly sensitive to petroleum pollution because their nervous systems and respiratory organs are very close to their skin which is thin; toxic substances can easily penetrate their bodies while their limited mobility prevents them from escaping polluted areas in time. Additionally, some hydrocarbons in petroleum share similar chemical signals (endocrine disruptors) or chemical structures with certain marine animals affecting their behavior.

(3) Soil pollution

Oil-containing wastewater flows directly into nearby soil through rainwater drainage systems; thus soil will be subject to certain levels of contamination; when surface water pollution occurs wastewater will flow overland through which surface soil will also be subject to certain levels of contamination.

1) Soil contaminated by oil exhibits weak alkaline or alkaline characteristics. Measurements show that pH values for soils from various oil fields are all above 7.17 with a maximum reaching 8.8.

2) The soluble salt content in contaminated soils is mostly above 0.2%, indicating salinization; some soil samples have soluble salt content exceeding 4%, indicating strong salinization.

3) In contaminated soils, available nitrogen (N) and available phosphorus (P) levels are relatively low.

Available nitrogen content is generally below 100 mg/kg; available phosphorus content is generally below 20 mg/kg accounting for about 5% of total phosphorus indicating typical nutrient-poor soils.

4) Contaminated soils have higher organic matter content mainly due to components from petroleum contamination being incorporated into organic matter.

5) The strong hydrophobicity of petroleum leads high-oil-content soils to exhibit hydrophobic characteristics; soil moisture retention capacity decreases while moisture content declines. When oil content exceeds 8%, soil moisture content generally does not exceed 5%; when oil content is below 8%, moisture content varies according to climatic conditions and soil types in oil field areas.

4 Analysis of the gap in existing environmental risk prevention and emergency measures

4.1 Analysis and suggestions for the overall environmental risk prevention measures gap

4.1.1 Analysis and suggestions for the engineering prevention measures gap

(1) Drainage collection measures

Gap analysis: The company adopts a rainwater and sewage diversion system. Rainwater is discharged through the existing rainwater pipeline network of Chongqing Shenlu Power Machinery Co., Ltd.; the company's production wastewater is treated by its self-built integrated sewage treatment facility with a capacity of 5m³/d, and then combined with domestic sewage into the biochemical pool on the west side of Shenlu Company, which has a treatment capacity of 30 m³/d. After meeting standards, it is discharged into the municipal sewage pipeline network, entering the sewage treatment plant in Area B of Luohuang Industrial Park for further treatment before being discharged into the Yangtze River via Ganzi Creek.

(2) Clean wastewater system prevention measures

Gap analysis: This company does not involve clean wastewater.

(3) Rainwater system prevention measures

Gap analysis: The company's rainwater is directly discharged into the rainwater pipeline network system of Luohuang Park.

4.1.2 Analysis of safety management prevention measures gap

Gap analysis: The company has not established relevant safety management systems.

Suggestions: It is recommended that the company establish an environmental management system according to the ISO14000 series; formulate environmental protection regulations and regulations for environmental protection positions; propose plans for the operation management of environmental protection facilities and improvement suggestions. Establish risk management systems for auxiliary material storage areas and hazardous waste temporary storage rooms, and maintain equipment maintenance systems and records.

4.1.3 Emergency management situation for environmental incidents

(1) Construction situation of emergency plans for environmental incidents

Gap analysis: The company is currently drafting emergency plans for sudden environmental incidents and has part-time environmental protection personnel. Suggestions: Collaborate with Hejia Machinery Company to prepare emergency plans for sudden environmental incidents. The formulated emergency plans must meet national requirements and should be highly operable; according to national regulations, when Hejia Machinery Company undergoes reconstruction or expansion, it needs to update the emergency plans to ensure normal emergency preparedness. The formulated emergency plans should be reviewed by experts and submitted to the Environmental Protection Bureau for filing.

Emergency material setup situation

(2) Gap analysis: Hejia Machinery Company has equipped a certain amount of emergency materials, such as fire extinguishers, fire water tanks, emergency lights, fire sand, etc., placed in obvious and easily accessible locations. However, there is a lack of certain emergency materials, such as oil-absorbing mats, oil-absorbing cotton, fire sand, etc.

Suggestions: The company should equip sufficient emergency materials and regularly check whether they can be effectively used.

Construction situation of emergency identification system

(3) Gap analysis: The company has not established a complete set of emergency identification systems.

Suggestions: Hejia Machinery Company should set up complete signage at various environmental risk units and key emergency points. When signs are found to be aging or unclear, they should be replaced in a timely manner so that the information reflected by each key point's signage can serve practical emergency purposes.

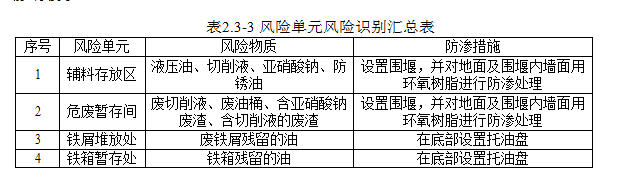

Analysis and suggestions for environmental risk source prevention measures gap

4.2 Auxiliary material storage area

(1) Gap analysis: The concrete floor of the auxiliary material storage area is treated with epoxy paint for corrosion resistance and seepage prevention. However, no bund has been set up to effectively prevent oil leakage.

Suggestions: Set up a bund in the auxiliary material storage area and treat the inner walls of the bund with epoxy resin for seepage prevention.

Hazardous waste temporary storage room

(2) Gap analysis: The floor and inner walls of the bund in the hazardous waste temporary storage room are only made of ordinary concrete without seepage treatment, and there are no labels for hazardous waste.

Suggestions: Treat the floor and inner walls of the bund in the hazardous waste temporary storage room with epoxy resin for seepage prevention, set up hazardous waste signage, and establish drainage ditches and collection tanks.

Iron chip storage area

(3) Gap analysis: The floor and inner walls of the bund in the iron chip storage area are only made of ordinary concrete without seepage treatment. Suggestions: Treat the floor and inner walls of the bund in the iron chip storage area with epoxy resin for seepage prevention, ensuring that the height is not less than that of iron chip stacking height, and set up drainage ditches and collection tanks.

(4)

Iron box temporary storage area

Gap analysis: The floor and inner walls of the bund in the iron box temporary storage area are only made of ordinary concrete without seepage treatment. Suggestions: Treat the floor and inner walls of the bund in the iron box temporary storage area with epoxy resin for seepage prevention, ensuring that it is not less than that of iron box stacking height. Emergency plan system

The emergency plan system includes content such as emergency rescue personnel, emergency materials, risk prevention control and emergency measures, emergency management systems, etc.

The list of internal emergency rescue personnel at Hejia Machinery Company can be found in Appendix 1; external emergency rescue agencies are listed in Appendix 2. Emergency materials at Hejia Machinery Company are detailed in Table 2.7-1. According to materials provided by the company and on-site inspections, Hejia Machinery Company's emergency materials do not meet requirements and need further improvement.

4.3 The risk prevention control and emergency measures of Hejia Machinery Company are detailed in Chapter 4.2.

According to materials provided by the company, Hejia Machinery Company has not established corresponding environmental risk management systems. Emergency plans for sudden environmental incidents are currently being drafted.

Summary of historical lessons learned

Although Hejia Machinery Company has not experienced any sudden environmental incidents since its establishment, substances like oil and sodium nitrite can easily leak, burn or explode when exposed to high temperatures, strong oxidizers or fire sources during storage or production processes, leading to environmental pollution or casualties.

Analyzing and summarizing cases of sudden environmental incidents from similar domestic enterprises collected earlier reveals that major causes of fire or explosion accidents in production device areas and tank areas include poor management, employee violations during operations, aging facilities (lack of maintenance), and transportation accidents.

4.4 Summary of Historical Experience and Lessons Learned

Although Hejia Machinery Company has not experienced any sudden environmental incidents since its establishment and production, oils, sodium nitrite, and other substances are flammable when exposed to high temperatures, strong oxidants, and sources of ignition. They may leak, burn, or explode during storage and production, causing environmental pollution or casualties.

Analyze and summarize the cases of sudden environmental incidents in similar domestic enterprises collected earlier. The main reasons for the occurrence of fire and explosion accidents in the production equipment area and storage tank area of the enterprises in the cases include: lax management, employees' illegal and irregular operations, aging facilities and equipment (lack of maintenance), and transportation accidents.

Although Hejia Machinery Company has not experienced any sudden environmental incidents since its establishment and production, oils, sodium nitrite, and other substances are flammable when exposed to high temperatures, strong oxidants, and sources of ignition. They may leak, burn, or explode during storage and production, causing environmental pollution or casualties.

Analyze and summarize the cases of sudden environmental incidents in similar domestic enterprises collected earlier. The main reasons for the occurrence of fire and explosion accidents in the production equipment area and storage tank area of the enterprises in the cases include: lax management, employees' illegal and irregular operations, aging facilities and equipment (lack of maintenance), and transportation accidents.

Hejia Machinery Company should take this as a warning and learn from historical experiences and lessons. In response to the causes of the aforementioned accidents, the following corresponding measures should be taken:

1. The company does not use production devices within the scope of the "Guidance Catalog for Eliminating Outdated Production Processes and Equipment in Certain Industrial Sectors (2010 Edition)" and the "Guidance Catalog for Industrial Structure Adjustment (2013 Revised Edition)" published by the Ministry of Industry and Information Technology. Regular maintenance and repairs are conducted, and problems are addressed promptly. If necessary, replacements are made to ensure that equipment meets load requirements and safety production standards.

2. Strengthen management, conduct regular employee training to improve employee quality and enhance operational skills; exams are conducted after internal and external training. Employee assessment results should be recorded for filing, with passing the exam deemed as qualified. Only those who pass the exam can operate; those who do not pass should continue remedial training until qualified, ensuring that they hold certificates when on duty; to enhance employees' initiative and awareness of standardized operations, internal reward and punishment measures should be formulated and implemented.

3. Strengthen emergency plan drills to improve employees' risk prevention awareness and emergency response capabilities.

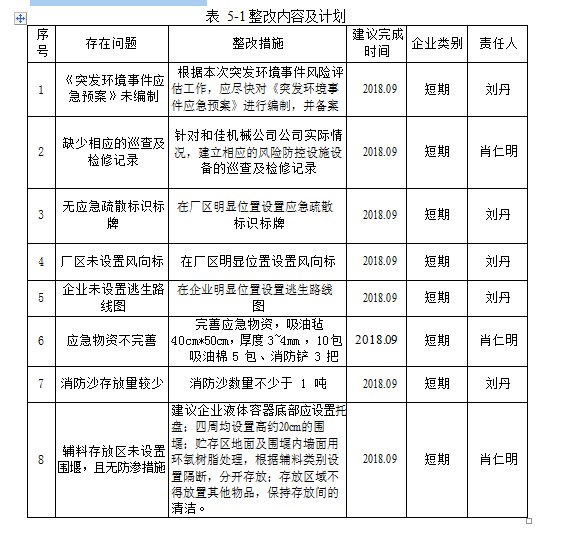

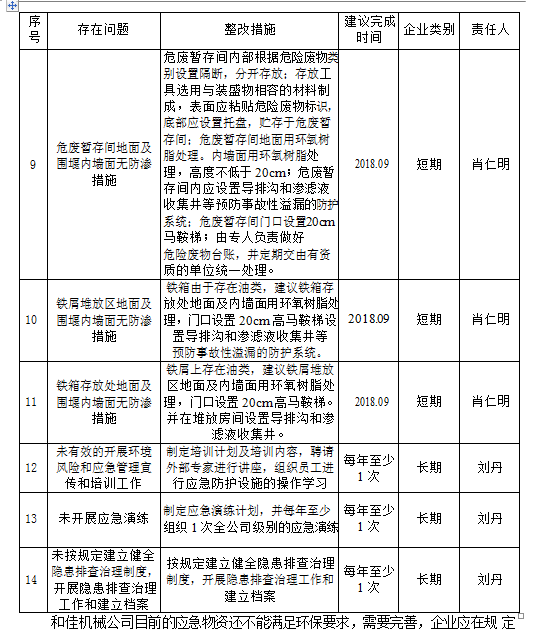

5. Improve the implementation plan for environmental risk prevention and emergency measures.

For each gap and hidden danger identified above, propose deadlines for rectification based on their harmfulness, urgency, and duration of governance, categorized as short-term (within 3 months), medium-term (3-6 months), and long-term (over 6 months).

6. Risk level of sudden atmospheric environmental events.

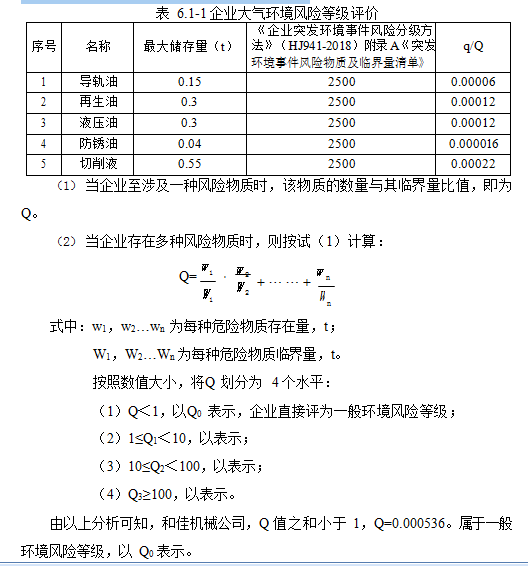

6.1 Calculate the ratio of the quantity of atmospheric risk substances to the critical amount (Q).

This evaluation report takes the auxiliary material storage area as the environmental risk source for evaluation.

According to the provisions of Appendix A "List of Risk Substances and Critical Amounts for Sudden Environmental Events" in the "Risk Classification Method for Sudden Environmental Events in Enterprises" (HJ941-2018), statistics on the storage amounts and critical amounts of raw materials and products involved in Hejia Machinery Company's risk assessment are shown in Table 6.1-1.

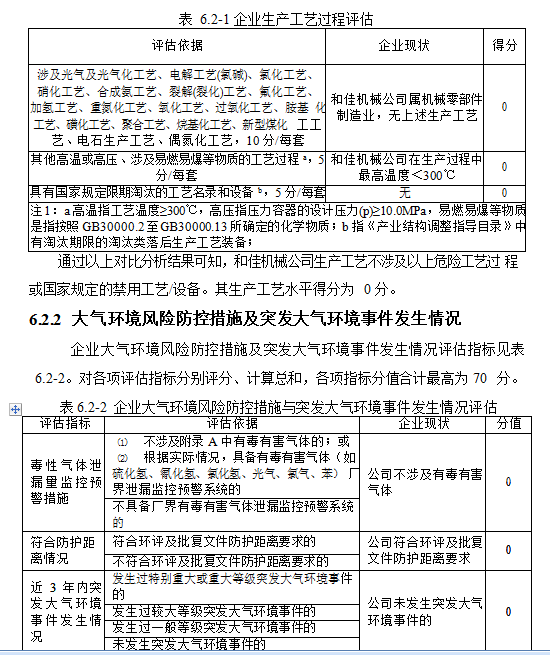

6.2 Assessment of production process and atmospheric environmental risk control level (M).

Using a scoring method to assess the production process, atmospheric environmental risk prevention measures, and occurrences of sudden atmospheric environmental events in enterprises, summing up scores for each indicator to determine the production process and atmospheric environmental risk control level (M).

6.2.1 The production process contains risky processes and equipment.

Hejia Machinery Company belongs to the manufacturing industry. By comparing with the "Catalog of Key Supervised Hazardous Chemical Processes" (2013 full version), there are no processes listed in this catalog or outdated production processes with elimination deadlines as stipulated by national regulations in Hejia Machinery Company's main production processes. The assessment basis for Hejia Machinery Company's production process is shown in Table 6.2-1.

The atmospheric environmental risk prevention measures and sudden atmospheric environmental event assessment score for Hejia Machinery Company is 0 points.

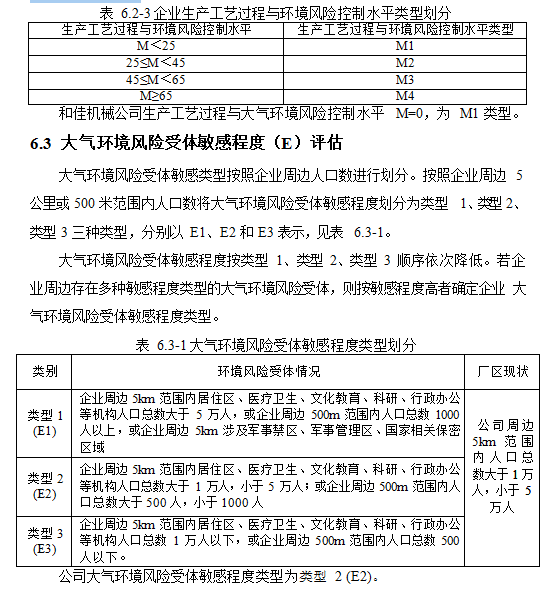

6.2.3 Production process and atmospheric environmental risk control level.

Summing up scores for each indicator related to the production process, atmospheric environmental risk prevention measures, and occurrences of sudden atmospheric environmental events yields a value for the production process and atmospheric environmental risk control level, categorized into four types according to Table 6.2-3.

6.4 Determination of risk level for sudden atmospheric environmental events.

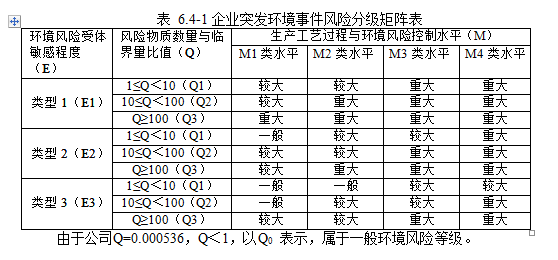

Based on the sensitivity degree (E) of atmospheric environment risk receptors surrounding the enterprise, the ratio of atmospheric risk substances quantity to critical amount (Q), and the production process with atmospheric environmental risk control level (M), determine the enterprise's sudden atmospheric environmental event risk level according to Table 6.4-1.

6.5 Characterization of sudden atmospheric environmental event risk level.

The characterization of enterprise sudden atmospheric environmental event risk levels is divided into two situations:

(1) When Q < 1, the enterprise's sudden atmospheric environmental event risk level is represented as "General - Atmosphere (Q0)".

(2) When Q ≥ 1, the enterprise's sudden atmospheric environmental event risk level is represented as "Environmental Risk Level - Atmosphere".

(Q Level - M Type - E Type).

Hejia Machinery Company has Q = 0.000536, Q < 1. Therefore, Hejia Machinery Company's sudden atmospheric environmental event risk level is "General - Atmosphere (Q0)".

7. Risk level for sudden water environment events.

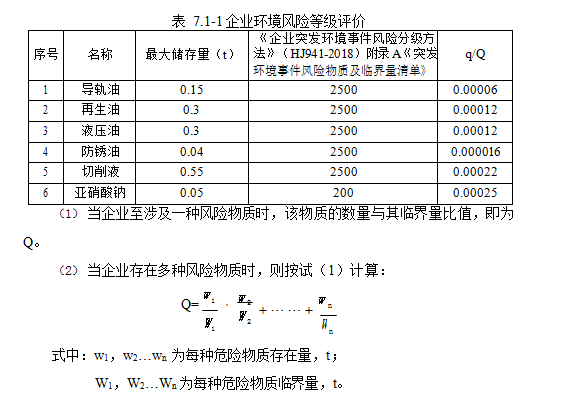

7.1 Calculate the ratio of water-related risk substances quantity to critical amount (Q).

This evaluation report takes the auxiliary material storage area as the environmental risk source for evaluation.

According to Appendix A "List of Risk Substances and Critical Amounts for Sudden Environmental Events" in the "Risk Classification Method for Sudden Environmental Events in Enterprises" (HJ941-2018), statistics on storage amounts and critical amounts of raw materials and products involved in Hejia Machinery Company's risk assessment are shown in Table 7.1-1.

According to numerical values, Q is divided into four levels:

(1) Q < 1 is represented as Q0; enterprises are directly rated as general environmental risk level;

(2) 1 ≤ Q < 10 is represented as;

(3) 10 ≤ Q < 100 is represented as;

(4) Q ≥ 100 is represented as.

From the above analysis, it can be seen that Hejia Machinery Company has a total Q value less than 1, with Q = 0.000786. It belongs to general environmental risk level, represented as Q0.

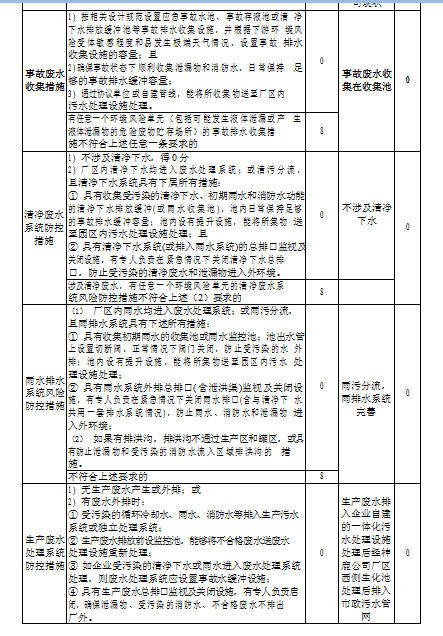

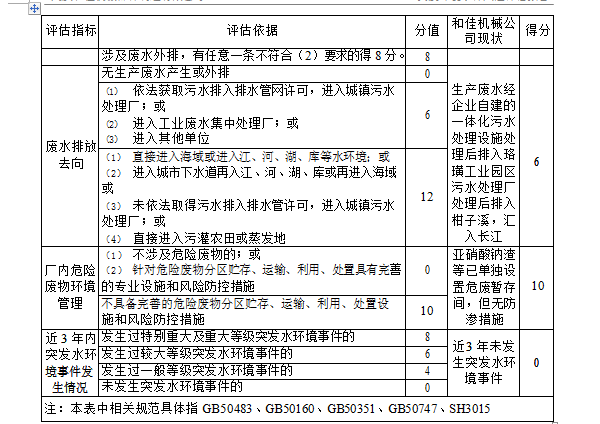

7.2 Assessment of production process and water environment risk control level (M).

Using a scoring method to assess the production process, water environment risk prevention measures, and occurrences of sudden water environment events in enterprises, summing up scores for each indicator to determine the production process with water environment risk control level (M).

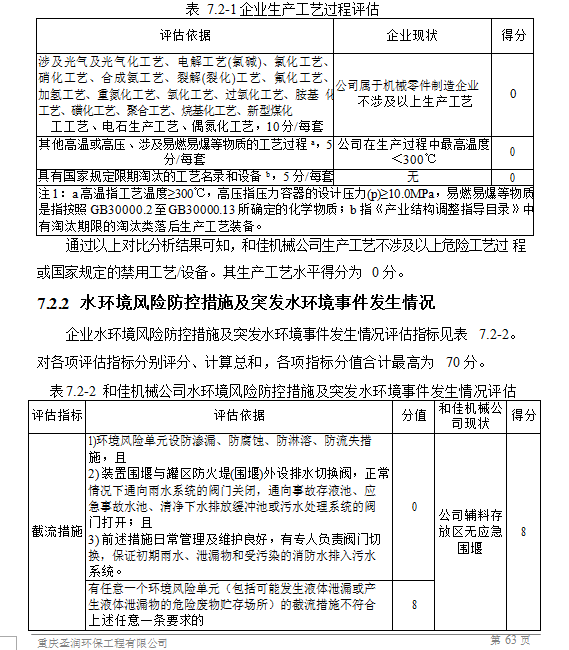

7.2.1 The production process contains risky processes and equipment.

Hejia Machinery Company belongs to a component manufacturing enterprise. By comparing with the "Catalog of Key Supervised Hazardous Chemical Processes" (2013 full version), there are no processes listed in this catalog or outdated production processes with elimination deadlines as stipulated by national regulations in Hejia Machinery Company's main production processes. The assessment basis for Hejia Machinery Company's production process is shown in Table 7.2-1.

7.2.3 Production process with water environment risk control level.

Summing up scores for each indicator related to the production process, water environment risk control measures, and occurrences of sudden water environment events yields a value for the production process with water environment risk control level according to Table 6.2-3.

Divided into four types.

The production process and water environment risk control level of Hejia Machinery Company is M=24, which is of type M1.

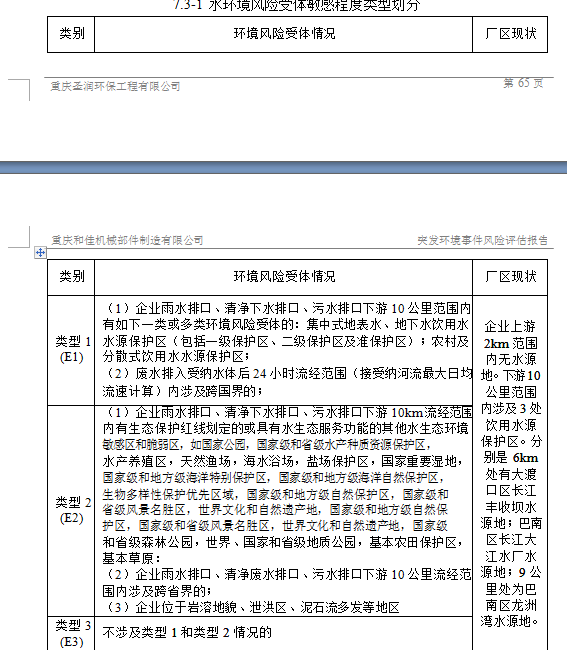

7.3 Assessment of the sensitivity of water environment risk receptors (E)

Based on the sensitivity of water environment risk receptors, while considering cross-border river situations and potential soil contamination, the sensitivity types of water environment risk receptors are classified into Type 1, Type 2, and Type 3, represented as E1, E2, and E3 respectively, see Table 7.3-1.

The sensitivity of water environment risk receptors decreases in the order of Type 1, Type 2, and Type 3. If there are multiple types of sensitive water environment risk receptors around the enterprise, the type with the highest sensitivity will determine the sensitivity type of the enterprise's water environment risk receptors.

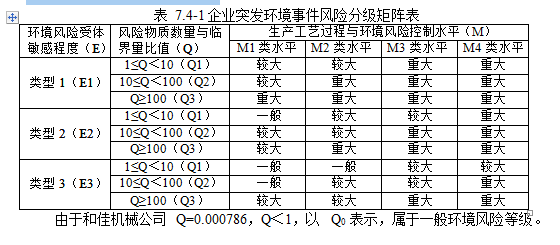

7.4 Determination of emergency water environment event risk level

Based on the sensitivity level (E) of water environment risk receptors around the enterprise, the ratio of the number of water-related risk substances to critical quantity (Q), and the production process and water environment risk control level (M), determine the emergency water environment event risk level of the enterprise according to Table 7.4-1.

7.5 Characterization of emergency water environment event risk level

The characterization of emergency water environment event risk levels for enterprises is divided into two situations:

(1) When Q < 1, the emergency water environment event risk level for the enterprise is represented as 'General - Water (Q0)'.

(2) When Q ≥ 1, the emergency water environment event risk level for the enterprise is represented as 'Environmental Risk Level - Water (Q Level - M Type - E Type)'.

Hejia Machinery Company has Q = 0.000786, Q < 1. Therefore, Hejia Machinery Company's emergency water environment event risk level is 'General - Water (Q0)'.

8. Determination and Adjustment of Enterprise Emergency Event Risk Levels

8.1 Risk Level Determination

Hejia Machinery Company's emergency atmospheric environmental event risk level is 'General - Atmosphere (Q0)', and the emergency water environment event risk level is 'General - Water (Q0)'. Therefore, Hejia Machinery Company's emergency event risk level is classified as a general environmental event risk level.

8.2 Risk Level Characterization

For enterprises involved in atmospheric environmental events and water environmental events, Hejia Machinery Company's risk level is represented as General [General - Atmosphere (Q0) + General - Water (Q0)].

9 Conclusion

Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. is a private enterprise specializing in the research and development, production, assembly, and sales of small agricultural machinery transmission assemblies such as tillers. Hejia Company invested 45 million yuan to rent factory buildings from Chongqing Shenlu Power Machinery Co., Ltd. in Area B of Luohuang Industrial Park in Jiangjin District, Chongqing City to establish a mechanical parts manufacturing enterprise. The company covers an area of about 4000 m2 with a building area of about 4200 m2, and its main products include agricultural machinery transmission boxes and gears, with an annual output capacity reaching one million pieces.

Analysis shows that Hejia Machinery Company is involved in both atmospheric environmental events and water environmental events; its risk level is represented as General [General - Atmosphere (Q0) + General - Water (Q0)].

Based on the analysis of gaps in existing environmental risk prevention and control measures at Hejia Machinery Company, corresponding rectification measures have been proposed that require further improvement. This aims to enhance the controllable level of environmental risks for the enterprise, reduce environmental risks, and prevent environmental accident occurrences. At the same time, it is recommended that enterprises improve corresponding pollution prevention measures and risk prevention measures based on rectification requirements proposed by the risk assessment.

10 Attachments and Figures

10.1 Figures

Figure 1: Geographic Location Map of the Enterprise

Figure 2: Distribution Map of Surrounding Environmental Risk Receptors

Figure 3: Layout Plan of the Enterprise (including Rainwater and Sewage Pipeline Map)

Figure 4: Distribution Map of Risk Sources in the Enterprise

Figure 5: Emergency Evacuation Route Map

Figure 6: Surrounding Traffic Road Map

Figure 7: Drinking Water Source Around the Enterprise

10.2 Attachments

Attachment 1: Internal Emergency Contact List of the Enterprise

Attachment 2: Contact List of External Emergency Rescue Agencies and Surrounding Units

Attachment 3: Hazardous Waste Disposal Agreement

Attachment 4: Expert Review Opinions

Prev

3.4.2 Diffusion Pathways of Risk Substances in Water Environment Under abnormal circumstances

2019-11-20

There are risks of leakage and fire during the transportation of raw materials such as guide rail oil

2019-11-20