All categories

20

2019

-

11

Risk Assessment Report for Sudden Environmental Incidents of Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. (1)

Author:

Emergency Environmental Incident Risk Assessment Report

Chongqing Hejia Machinery Parts Manufacturing Co., Ltd.

Emergency Environmental Incident Risk Assessment Report

Prepared by: Chongqing Shengrun Environmental Protection Engineering Co., Ltd.

Preparation Date: August 2018

Responsibility Table

Responsible Personnel Last Name First Name Administrative Position Technical Position Signature First Name

Unit Leader Li Yang General Manager /

Project Leader Wang Zhongcai / Technician

Report Technical Responsible Person Su Hui Deputy General Manager Engineer

Report Reviewer Li Xiaoli / Engineer

Report Writing Section Last Name First Name Technical Position Qualification Certificate Signature First Name

Chapters 1-4 Wang Zhongcai Technician /

Chapters 5-10 Gong Xiaowei Technician /

Preface

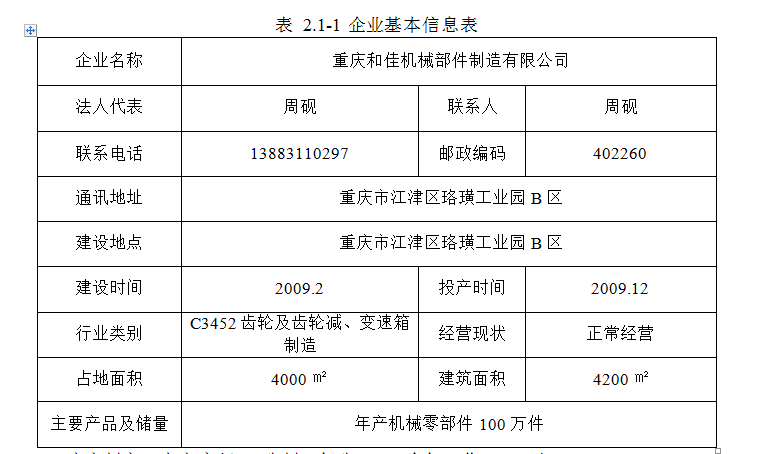

Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. (hereinafter referred to as 'Hejia Machinery Company') is a private enterprise specializing in the research and development, production, assembly, and sales of small agricultural machinery gearboxes such as tillers. Hejia Machinery Company invested 45 million yuan to rent a factory building from Chongqing Shenlu Power Machinery Co., Ltd. in Area B of Luohuang Industrial Park, Jiangjin District, Chongqing City to establish a mechanical parts manufacturing enterprise. The company covers an area of approximately 4000 m2, with a building area of about 4200 m2, and its main products include agricultural machinery transmission boxes and gears, with an annual output of one million mechanical parts.

In accordance with the relevant regulations of the 'Environmental Protection Law of the People's Republic of China', 'Notice on Further Strengthening Environmental Impact Assessment Management to Prevent Environmental Risks', 'Regulations on the Safe Production Management of Hazardous Chemicals', and the Chongqing Municipal Environmental Protection Bureau's 'Notice on Standardizing Emergency Plans and Risk Assessment Management for Sudden Environmental Incidents', Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. entrusted Chongqing Shengrun Environmental Protection Engineering Co., Ltd. to conduct a risk assessment for sudden environmental incidents at Hejia Machinery Company. After accepting the commission, our unit immediately organized professionals to conduct on-site surveys, investigations, and collect relevant data. In accordance with the requirements of the 'Guidelines for Risk Assessment of Sudden Environmental Incidents in Enterprises (Trial)' and 'Methods for Risk Classification of Sudden Environmental Incidents in Enterprises (HJ 941-2018)', we completed the 'Emergency Environmental Risk Assessment Report for Chongqing Hejia Machinery Parts Manufacturing Co., Ltd.'

According to the provisions of the 'Catalog of Hazardous Chemicals' (2015 Edition), 'List of Dangerous Goods' (GB12268-2012), and 'Identification of Major Hazards of Hazardous Chemicals' (GB-18218-2009), the cutting fluid, hydraulic oil, rust-proof oil, and sodium nitrite used by Hejia Machinery Company are classified as environmentally hazardous substances. In the event of pollution accidents such as oil or cutting fluid leaks, they may contaminate surrounding soil and water bodies, causing personnel poisoning. If there is an open flame, it may also lead to fires or explosions, resulting in personal injury and property loss. Therefore, conducting a risk assessment for Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. to identify risk sources, understand regional environmental risk sensitivity characteristics, determine environmental risk protection objectives, analyze and predict potential environmental pollution incidents and their impact extent and scope, strengthen emergency capability construction, and ensure that the environmental risk level of Hejia Machinery Company remains within controllable limits is extremely important and necessary.

Table of Contents

Preface I

Table of Contents I

1 General Principles 1

1.1 Preparation Principles 1

1.1.1 Purpose of Preparation 1

1.1.2 Preparation Principles 1

1.2 Basis for Preparation 1

1.2.1 Environmental Protection Laws, Regulations, and Rules 1

1.2.2 Relevant Technical Standards 2

1.2.3 Local Policies and Regulations 3

1.2.4 Other Materials and Documents 4

1.3 Risk Assessment Procedures for Sudden Environmental Incidents in Enterprises 4

1.4 Assessment Scope 5

2 Data Preparation and Environmental Risk Identification 6

2.1 Basic Information of the Enterprise 6

2.1.1 Basic Information 6

2.1.2 Production Overview 6

2.1.3 Process Flow 9

2.1.4 Generation and Emission of Pollutants 13

2.1.5 Plane Layout 15

2.1.6 Public Works 15

2.2 Geographic Location and Surrounding Environment 16

2.2.1 Geographic Location 16

2.2.2 Natural Environment 16

2.2.3 Environmental functional zones 18

2.2.4 External Environment of Enterprises 19

2.3 Environmental Risk Identification 19

2.3.1 Substances Involving Environmental Risks 19

2.3.2 Identification of Environmental Risks in Production Process 20

2.3.3 Identification of Environmental Risks during Storage Process 21

2.3.4 Environmental risk identification during transportation 21

2.3.5 times/associated risk identification 21

2.3.6 Identification of Major Hazardous Sources 22

2.4 Situation of risk receptors in the surrounding environment of the enterprise 22

2.4.1 Atmospheric Environment Risk Receptors 23

2.4.2 Soil Environmental Risk Receptors 24

2.4.3 Water Environment Risk Receptors 24

2.5 Safety Production Management (excerpt from the self-made system of Hejia Machinery Company) 24

2.6 Current situation of environmental risk prevention and emergency measures 26

2.6.1 Current situation of environmental risk prevention and emergency measures 26

2.6.2 Rationality Analysis of Emergency Facilities for Accidents 27

2.7 Current emergency supplies and equipment, and rescue team situation 28

2.7.1 Existing emergency materials and equipment 28

2.1.2 Production Overview 6

2.1.3 Process Flow 9

2.1.4 Generation and Emission of Pollutants 13

2.1.5 Plane Layout 15

2.1.6 Public Works 15

2.2 Geographic Location and Surrounding Environment 16

2.2.1 Geographic Location 16

2.2.2 Natural Environment 16

2.2.3 Environmental functional zones 18

2.2.4 External Environment of Enterprises 19

2.3 Environmental Risk Identification 19

2.3.1 Substances Involving Environmental Risks 19

2.3.2 Identification of Environmental Risks in Production Process 20

2.3.3 Identification of Environmental Risks during Storage Process 21

2.3.4 Environmental risk identification during transportation 21

2.3.5 times/associated risk identification 21

2.3.6 Identification of Major Hazardous Sources 22

2.4 Situation of risk receptors in the surrounding environment of the enterprise 22

2.4.1 Atmospheric Environment Risk Receptors 23

2.4.2 Soil Environmental Risk Receptors 24

2.4.3 Water Environment Risk Receptors 24

2.5 Safety Production Management (excerpt from the self-made system of Hejia Machinery Company) 24

2.6 Current situation of environmental risk prevention and emergency measures 26

2.6.1 Current situation of environmental risk prevention and emergency measures 26

2.6.2 Rationality Analysis of Emergency Facilities for Accidents 27

2.7 Current emergency supplies and equipment, and rescue team situation 28

2.7.1 Existing emergency materials and equipment 28

2.7.2 Existing emergency rescue teams 28

2.8 Hidden dangers and risk prevention measures for emergency management of sudden environmental incidents in enterprises 29

3 Analysis of sudden environmental incidents and their consequences 35

3.1 Scenario analysis of sudden environmental incidents 35

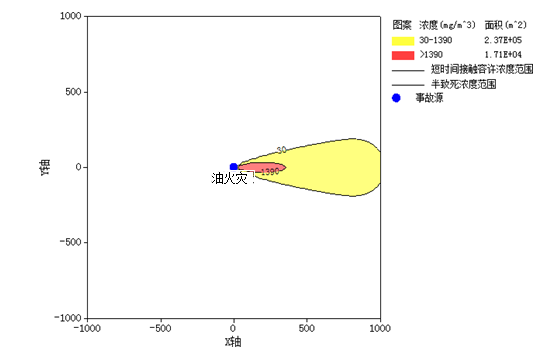

3.2 Maximum credible accidents and types 39

3.2.1 Leakage accidents 39

3.2.2 Fire and explosion accidents 39

3.2.3 Environmental pollution accidents 40

3.3 Source strength analysis of sudden environmental incident scenarios 40

3.3.1 Prediction of source strength for leakage accidents in storage areas 41

3.3.2 Prediction of source strength for fire and explosion accidents in storage areas 41

3.3.3 Calculation of wastewater volume from accidents 41

3.4 Diffusion pathways of released environmental risk substances 42

3.4.1 Diffusion pathways of atmospheric environmental risk substances 42

3.4.2 Diffusion pathways of water environmental risk substances 44

3.5 Analysis of the harmful consequences of sudden environmental incidents 49

3.5.1 Analysis of the consequences of leakage accidents 49

3.5.2 Analysis of the consequences of fire and explosion accidents 49

3.5.3 Analysis of the consequences of environmental pollution accidents 49

4 Analysis of gaps in existing environmental risk prevention and emergency measures 53

4.1 Analysis and suggestions for gaps in overall environmental risk prevention measures 53

4.1.1 Analysis and suggestions for gaps in engineering prevention measures 53

4.1.2 Analysis of gaps in safety management prevention measures 53

4.1.3 Emergency management situation for environmental incidents 53

4.2 Analysis and suggestions for gaps in prevention measures for environmental risk sources 54

4.3 Emergency plan system 54

5 Implementation plan to improve environmental risk prevention and emergency measures 56

6 Risk levels of sudden atmospheric environmental incidents 58

6.1 Calculate the ratio (Q) of the quantity of atmospheric risk substances to the critical amount 58

6.2 Assessment of production process and atmospheric environmental risk control level (M) 58

6.2.1 Risk processes and equipment in the production process 59

6.2.2 Atmospheric environmental risk prevention measures and occurrence of sudden atmospheric environmental incidents - 59

6.2.3 Production process and atmospheric environmental risk control level in enterprises 60

6.3 Assessment of sensitivity (E) to atmospheric environmental risks 60

6.4 Determination of risk levels for sudden atmospheric environmental incidents 60

6.5 Characterization of risk levels for sudden atmospheric environmental incidents 61

7 Risk levels for sudden water environment incidents 62

7.1 Calculate the ratio (Q) of the quantity of water-related risk substances to the critical amount 62

7.2 Assessment of production process and water environment risk control level (M) 62

7.2.1 Risk processes and equipment in the production process 63

7.2.2 Water environment risk prevention measures and occurrence of sudden water environment incidents 63

7.2.3 Production process and water environment risk control level in enterprises 65

7.3 Assessment of sensitivity (E) to water environment risks 65

7.4 Determination of risk levels for sudden water environment incidents 66

7.5 Characterization of risk levels for sudden water environment incidents 67

8. Determination and adjustment of enterprise sudden environmental incident risk levels 68

8.1 Risk level determination 68

8.2 Risk level characterization 68

(9) Conclusion 69

(10) Attachments, figures 70

(10.1) Figures 70

(10.2) Attachments 70

(1) General principles

1.1 Preparation Principles

1.1.1 Purpose of Preparation

(Enterprise environmental incident risk assessment is conducted through an in-depth investigation into various production links within the enterprise, identifying and analyzing sources, pathways, and receptors of environmental risks, analyzing potential sudden environmental incidents and their consequences, identifying gaps in existing environmental risk prevention and emergency management, proposing scientifically reasonable corrective measures and suggestions, thereby improving the enterprise's technical level in preventing and controlling environmental risks, preventing and reducing the emergence of unstable factors from the source, reducing the frequency of sudden environmental incidents, mitigating environmental pollution hazards, reducing personnel injuries, minimizing property losses, and providing a scientific basis for regulatory authorities to implement differentiated tiered environmental risk management, improving management efficiency, and constructing a government system for preventing environmental risks and managing emergency responses.)

(This enterprise's risk assessment aims to reduce the frequency of sudden environmental incidents at Jia Mechanical Company, mitigate pollution hazards to the factory area and surrounding environment, reduce personnel injuries, and minimize property losses.)

1.1.2 Preparation Principles

(1) (Implement national and local environmental protection policies and regulations, adhere to standards compliance, pollution prevention, and controllable risks principles, serving the purpose of environmental management.)

(2) (Enhance the practicality and scientific nature of environmental risk assessments to ensure the quality of assessment reports, providing a scientific basis for environmental management.)

(3) (The compilation adopts principles that are 'objective, fair, and pragmatic.')

(4) (From an environmental protection perspective, provide justification for the enterprise's risk level while striving to ensure that evaluation conclusions are scientific and practical, providing a scientific basis for enterprise environmental protection management.)

1.2 Basis for Preparation

1.2.1 Environmental Protection Laws, Regulations, and Rules

(1) (Environmental Protection Law of the People's Republic of China (implemented on January 1, 2015);)

(2) (Water Pollution Prevention Law of the People's Republic of China (effective from January 1, 2018);)

(3) (Air Pollution Prevention Law of the People's Republic of China (effective from January 1, 2016);)

(4) (Solid Waste Pollution Prevention Law of the People's Republic of China (revised on November 7,2016);)

(5) (Production Safety Law of the People's Republic of China (effective from December1,2014);)

(6) Emergency Response Law of the People's Republic of China (effective from November 1, 2007);

Fire Protection Law of the People's Republic of China (revised on October 28, 2008); Land Administration Law of the People's Republic of China (revised on August 28, 2004);

Regulations on the Safety Management of Hazardous Chemicals (State Council Order No. 645, revised on December 7, 2013); Safety Specifications for the Construction and Storage of Hazardous Chemical Warehouses (DB11755-2010);

Measures for Reporting Information on Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 17); Management Measures for Emergency Plans for Sudden Incidents (Guo Ban Fa [2013] No. 101);

Opinions of the State Council on Strengthening Key Work in Environmental Protection (Guo Fa [2011] No. 35); Interim Measures for the Management of Emergency Plans for Sudden Environmental Incidents (Huan Fa [2010] No. 113);

Emergency Management Measures for Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 34) Guidance Catalog for Industrial Structure Adjustment (2013 revised edition);

List of Hazardous Chemicals Under Key Supervision (An Jian Zong Guan San [2011] No. 95); Notice on the List of Hazardous Chemicals Under Key Supervision (An Jian Zong Guan San [2013] No. 12);

Catalog of Hazardous Chemicals (2015 edition); National Hazardous Waste List (2016 edition);

Regulations on the Management of Precursor Chemicals (2014 revised edition); Catalog of Highly Toxic Substances (Wei Fa Jian Fa [2003] No. 142);

Catalog of Hazardous Chemicals Under Key Environmental Management (Huan Ban [2014] No. 33) Safety Measures and Emergency Response Principles for the First Batch of Hazardous Chemicals Under Key Supervision (An Jian Zong Ting Guan San [2011] No. 142);

Safety Measures and Emergency Response Principles for the Second Batch of Hazardous Chemicals Under Key Supervision (An Jian Zong Guan San [2013] No. 12); Management Measures for Hazardous Waste Transfer Tracking Forms (Former National Environmental Protection Administration Order No. 5);

Notice on Issuing the Recommended Methods for Environmental Damage Assessment and Evaluation (Version II) (Huan Ban [2014] No. 90). Identification of Major Hazards in Hazardous Chemicals (GB18218-2009);

Comprehensive Discharge Standards for Sewage (GB8976-1996); (3) List of Dangerous Goods Names (GB12268-2012);

(4) Classification and Naming Codes for Dangerous Goods (GB6944-2005); (5) Fire Protection Design Code for Buildings (GB50016-2014);

Fire Protection Design Code for Petrochemical Enterprises (GB50160-2008); Safety Regulations for Classification, Warning Labels, and Safety Instructions for Chemicals (GB20576-GB20602);

Technical Guidelines for Environmental Risk Assessment in Construction Enterprises (HJ/T169-2004); Safety Technical Supervision Regulations for Fixed Pressure Vessels (TSG R0004-2009);

(Technical Requirements for Prevention and Control of Water Pollution in Accidental Situations) (China Petroleum Enterprise Standard Q/SY1190-2013); (Operational Management Requirements for Risk Prevention and Control Measures in Water Pollution Accidents) (China Petroleum Enterprise Standard Q/SY1310-2010);

Pollution Control Standards for Hazardous Waste Storage (GB18597-2001); Technical Specifications for Collection, Storage, and Transportation of Hazardous Waste (HJ2025-2012);

Technical Specifications for Emergency Monitoring of Sudden Environmental Incidents (HJ589-2010); (Risk Classification Method for Sudden Environmental Incidents in Enterprises) (HJ941-2018);

(General Rules for Storing Common Chemical Hazards) (GB15603-1995); (Detection Procedures for Classifying the Degree of Harm from Dust Operations) (LD84-1995);

(18) Classification of Toxic Operations (GB12331-1990); (Classification and Codes of Dangerous and Harmful Factors in Production Processes) (GB/T13861-2009);

(Classification of Employee Casualty Accidents in Enterprises) (GB/T6441-1986); (Guidelines for Risk Assessment of Sudden Environmental Incidents in Enterprises - Trial Implementation);

1.2.2 Relevant Technical Standards

(1) (Comprehensive Emission Standards for Air Pollutants in Chongqing) (DB50/418-2016).

(2) Integrated Wastewater Discharge Standard (GB8976-1996);

(3) List of Dangerous Goods (GB12268-2012);

(4) Classification and Numbering of Dangerous Goods (GB6944-2005);

(5) Code for Fire Protection Design of Buildings (GB50016-2014);

(6) Fire Prevention Design Code for Petrochemical Enterprises (GB50160-2008);

(3) List of Dangerous Goods (GB12268-2012);

(4) Classification and Numbering of Dangerous Goods (GB6944-2005);

(5) Code for Fire Protection Design of Buildings (GB50016-2014);

(6) Fire Prevention Design Code for Petrochemical Enterprises (GB50160-2008);

Fire Protection Law of the People's Republic of China (revised on October 28, 2008); Safety Regulations for Classification, Warning Labels, and Warning Instructions of Chemicals(GB20576-GB20602);

Regulations on the Safety Management of Hazardous Chemicals (State Council Order No. 645, revised on December 7, 2013); Technical Guidelines for Environmental Risk Assessment of Construction Enterprises(HJ/T169-2004) ;

Measures for Reporting Information on Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 17); Safety Technical Supervision Regulations for Fixed Pressure Vessels(TSG R0004-2009);

Opinions of the State Council on Strengthening Key Work in Environmental Protection (Guo Fa [2011] No. 35); Technical Requirements for Prevention and Control of Water Pollution in Accident Situations (China Petroleum Enterprise Standard)

Q/SY1190-2013);

Q/SY1190-2013);

Emergency Management Measures for Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 34) Requirements for the Operation and Management of Risk Prevention and Control Measures for Water Pollution Accidents (Chinese Petroleum Enterprise Standard Q/SY1310-2010);

List of Hazardous Chemicals Under Key Supervision (An Jian Zong Guan San [2011] No. 95); Standard for Pollution Control on Hazardous Waste Storage (GB18597-2001);

Catalog of Hazardous Chemicals (2015 edition); Technical Specifications for Collection, Storage, and Transportation of Hazardous Waste (HJ2025-2012);

Regulations on the Management of Precursor Chemicals (2014 revised edition); Technical Specification for Emergency Monitoring of Sudden Environmental Incidents (HJ 589-2010);

Catalog of Hazardous Chemicals Under Key Environmental Management (Huan Ban [2014] No. 33) Risk Grading Method for Sudden Environmental Incidents in Enterprises (HJ941-2018);

Safety Measures and Emergency Response Principles for the Second Batch of Hazardous Chemicals Under Key Supervision (An Jian Zong Guan San [2013] No. 12); General rules for storage of commonly used hazardous chemicals (GB15603-1995);

Notice on Issuing the Recommended Methods for Environmental Damage Assessment and Evaluation (Version II) (Huan Ban [2014] No. 90). Classification and Testing Regulations for Hazards of Productive Dust Operations (LD 84-1995);

(18) Classification of Toxic Operations (GB12331-1990);

(18) Classification of Toxic Operations (GB12331-1990);

(4) Classification and Naming Codes for Dangerous Goods (GB6944-2005); Classification and Code of Hazardous and Harmful Factors in Production Process (GB/T13861-2009);

Fire Protection Design Code for Petrochemical Enterprises (GB50160-2008); Classification of Occupational Injury Accidents in Enterprises (GB/T6441-1986);

Technical Guidelines for Environmental Risk Assessment in Construction Enterprises (HJ/T169-2004); Guidelines for Risk Assessment of Sudden Environmental Incidents in Enterprises (Trial);

(Technical Requirements for Prevention and Control of Water Pollution in Accidental Situations) (China Petroleum Enterprise Standard Q/SY1190-2013); Comprehensive Emission Standards for Air Pollutants in Chongqing (DB 50/418-2016).

1.2.3 Local Policies and Regulations

(1) Chongqing Environmental Protection Regulations (2017 Edition);

(2) Chongqing Yangtze River Three Gorges Reservoir Area and Basin Water Pollution Prevention Regulations (Revised in 2011);

(3) Regulations on the Division of Functional Areas for Ambient Air Quality in Chongqing (Yufu Fa [2016] No. 19);

(4) Notice from the Chongqing Municipal People's Government on the Adjustment Plan for Surface Water Environmental Function Categories (Yufu Fa [2012] No. 4);

(5) Measures for the Prevention and Control of Drinking Water Source Pollution in Chongqing;

(6) Chongqing Emergency Response Regulations (Effective July 1, 2012);

Fire Protection Law of the People's Republic of China (revised on October 28, 2008); Notice from the Chongqing Environmental Protection Bureau on Strengthening Risk Assessment of Sudden Environmental Events in Enterprises (Yuhuan [2014] No. 121);

[2014] No. 121);

Regulations on the Safety Management of Hazardous Chemicals (State Council Order No. 645, revised on December 7, 2013); Notice from the Office of the Chongqing Environmental Protection Bureau on Further Strengthening the Compilation and Filing Management of Emergency Plans for Sudden Environmental Events in Enterprises and Institutions (Yuhuan Ban [2017] No. 165);

Measures for Reporting Information on Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 17); Notice from the Office of the Chongqing Environmental Protection Bureau on Deepening Information Registration of Key Risk Enterprises and Industrial Parks for Sudden Environmental Events and Enhancing Emergency Plan Management (Yuhuan Ban [2017] No. 130);

Opinions of the State Council on Strengthening Key Work in Environmental Protection (Guo Fa [2011] No. 35); Management Measures for the Operation of the Early Warning Information Release Platform for Sudden Events in Chongqing (Trial) (Yufu Ban Fa [2016] No. 75);

Emergency Management Measures for Sudden Environmental Incidents (Ministry of Environmental Protection Order No. 34) Emergency Notice from the Office of the Chongqing Environmental Protection Bureau on Further Strengthening Environmental Risk Prevention Work in Chemical Enterprises (Yuhuan Ban Fa [2015] No. 108).

1.2.4 Other Materials and Documents

(1) Environmental Impact Assessment Report Form for Mechanical Parts Manufacturing Project of Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. (Chongqing Hengde Environmental Protection Technology Co., Ltd., January 2018);

(2) Other relevant documents or materials provided by the enterprise.

1.3 Risk Assessment Procedures for Sudden Environmental Incidents in Enterprises

By quantitatively analyzing the ratio (Q) of the quantity of all environmental risk substances produced, processed, used, and stored by enterprises to their critical values, assess the process and environmental risk control level (M) as well as the sensitivity of environmental risk receptors (E), and classify the risk levels of sudden environmental events in enterprises using a matrix method.

The classification of environmental risk levels is divided into three levels: general environmental risk, larger environmental risk, and major environmental risk, marked by blue, yellow, and red respectively.

1.4 Assessment Scope

Based on the actual situation of Chongqing Hejia Machinery Parts Manufacturing Co., Ltd. (hereinafter referred to as 'Hejia Machinery Company'), this risk assessment covers the following scope:

(1) Production operation sites;

(2) Auxiliary material storage areas;

(3) Hazardous waste temporary storage rooms;

(4) Solid waste temporary storage areas;

(5) Atmospheric risk receptors within a radius of 5 kilometers around the factory area;

(6) Water environment risk receptors within a range of 2 kilometers upstream and 10 kilometers downstream from the factory area.

Data Preparation and Environmental Risk Identification

2.1 Basic Information of the Enterprise

2.1.1 Basic Information

Production System: The production operates on a two-shift system, with each shift lasting 8 hours, working a total of 330 days a year.

Labor Staffing: The total number of production and management personnel in the enterprise is 90, including management staff of 10.

2.1.2 Production Overview

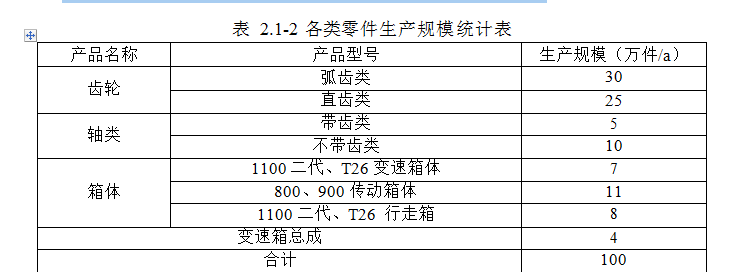

(1) Production Scale of Various Products

The production scale statistics for various parts by Hejia Machinery Company are shown in Table 2.1-2.

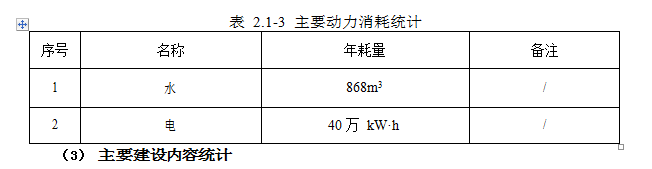

(2) Energy Consumption Statistics

Main energy consumption statistics are shown in the table below.

2.1.3 Process flow

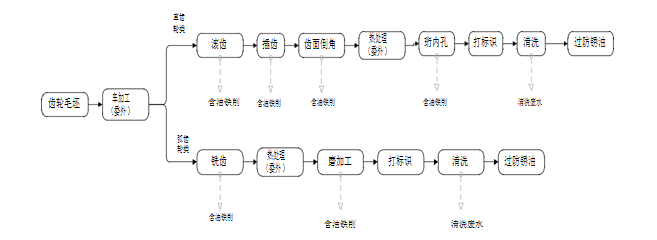

The enterprise mainly processes blank parts for small agricultural machinery transmission boxes and assembles agricultural machinery components. The main production processes for transmission box components can be divided into three categories: gears, shafts, and housings, with a main assembly line for transmission box assemblies. The specific production process flow and pollutant discharge links are shown in Figures 2.1-1, 2.1-2, 2.1-3, and 2.1-4. The overall production process flow is shown in Figure 2.1-1.

(1) Gear Production Process and Pollutant Discharge Links

Figure 2.1-1 Gear Processing Production Line Process Flow and Pollutant Discharge Links Diagram

Process Flow Description: The gears produced by this enterprise are divided into straight gears and helical gears. All purchased blank parts are processed externally; after turning processing is completed, they enter different production processes based on straight or helical gears. The processes include gear milling, gear hobbing, gear shaping, tooth face chamfering, honing inner holes, etc., where waste hydraulic oil is continuously used to wash workpieces during operation to achieve lubrication and remove iron filings generated during processing. According to information provided by the owner, approximately 33 tons/year of oily iron filings are produced; this enterprise uses an oil removal machine to treat oily iron filings, resulting in about 25.5 tons/year of de-oiled iron filings and approximately 7.5 tons/year of regenerated oil.

Straight Gears

(a) Hobbing: The manufacturing of involute cylindrical gear teeth is called 'hobbing', which uses a hob to process hobbing blanks; the envelope curve of hob teeth forms the involute teeth profile of workpieces; this process generates oily iron filings.

(b) Shaping: Using shaping cutters to process internal and external gear tooth surfaces by either generating or forming methods. Shaping cutters are equivalent to a pair of parallel cylindrical gears meshing with each other; essentially it is a gear with front and back angles that has cutting edges; this process generates oily iron filings.

(c) (d) Tooth Face Chamfering: To prevent tooth edges from colliding and causing damage when straight gears shift into working positions easily, this enterprise uses a gear chamfering machine to chamfer workpieces. The gear chamfering machine employs a double-cutter separation structure; after one tooth is cut, it indexes to start cutting again after completing one rotation.

(e) (e) Heat Treatment: This enterprise conducts heat treatment through outsourcing.

(f) Honing inner hole: Using honing oil stone strips installed on the honing machine head to perform finishing grinding on the surface of workpieces that require fine processing, also known as boring and grinding. Honing can achieve higher roundness, cylindricity, surface roughness, and dimensional accuracy of the inner hole, and this process generates oil-containing iron filings.

Marking: Using a laser printer to mark the letters "HJ" on the workpiece.

g Cleaning: Add a certain proportion of cleaning agent and water to the cleaning machine, which uses electric heating for heating, with a heating temperature of about 40~70℃, to clean the gears and then dry them. The entire process is carried out in a closed environment within the cleaning machine, and this process generates cleaning wastewater.

h Rust-proof oil application: This company applies rust-proof oil to the gears using an oil immersion method for surface rust protection. Arc gear types.

a Milling teeth: Using milling cutters on the milling machine to process the tooth surfaces of gears by the shaping method, this process generates oil-containing iron filings.

b Heat treatment: Outsourced.

Grinding: Using an external cylindrical grinding machine to grind the gears. This process requires diluting sodium nitrite and water in a ratio of 1:50 before adding it to the grinding machine for lubrication and rust prevention. Sodium nitrite water needs to be replenished daily after consumption, with a replenishment amount of about 10kg/d. Wastewater is recycled and not discharged externally. This company collects wastewater approximately every half month, which contains sodium nitrite waste residue.

(e) Marking: Using a laser printer to mark the letters "HJ" on the workpiece.

(f) Cleaning: Add a certain proportion of cleaning agent and water to the cleaning machine, which uses electric heating for heating, with a heating temperature of about 40~70℃, to clean the gears and then dry them. Finally, manually spray rust-proof oil on the gears for rust protection. This process generates cleaning wastewater.

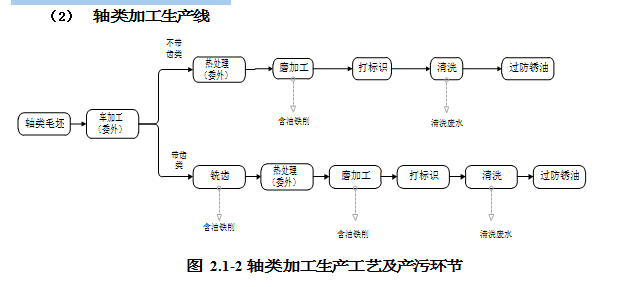

Process flow description:

Figure 2.1-2 Processing production technology and pollution generation links for shaft types.

The production line for gear shafts is divided into toothed shafts and non-toothed shafts. The turning processing and heat treatment of shaft-type workpieces are both outsourced. The production processes for both types of gear shafts are roughly similar, with an additional milling teeth process for toothed shafts. After outsourcing heat treatment, this company needs to perform grinding processing and mark "HJ" on the workpieces. The pollution generation links in the entire shaft production line include oil-containing iron filings generated from the milling teeth process, sodium nitrite waste residue generated from grinding processing, and cleaning wastewater generated from the cleaning process.

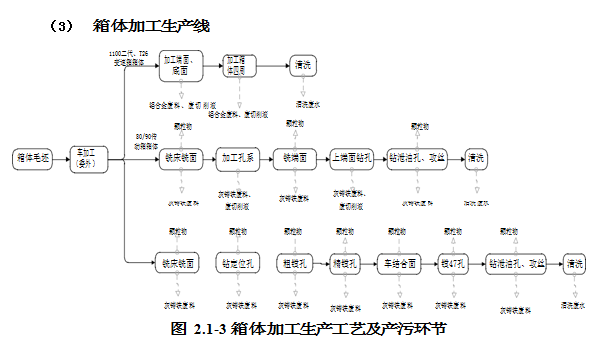

According to box-type products, they can be divided into three types based on their material and performance: 1100 second generation and T26 gearbox housings, 800 and 900 transmission box housings, and 1100 and T26 travel box housings. The processing production technology varies for different housings; specific production processes and pollution generation links are as follows:

1100 second generation, T26 gearbox housing

The production line for the 1100 second generation and T26 gearbox (also includes some other models of aluminum alloy gearboxes and front boxes) is made of aluminum alloy material with small machining allowances. It only has three processes: first machining the upper and lower surfaces of the housing; second using a four-axis rotary table to machine all four sides of the part. These two processes are performed in a machining center with cutting fluid added. Finally, the workpiece is placed in a cleaning machine for cleaning. The main pollutants generated by this production line are aluminum alloy waste materials, waste cutting fluid, and cleaning wastewater.

800, 900 transmission box housing

This type of housing is made of HT200 material (gray cast iron), with low blank precision and large machining allowances. Due to lower milling efficiency in machining centers compared to milling machines, this processing technology combines high-efficiency milling machines for face milling with specialized machines designed according to product design for machining around the housing, end faces, and hole systems. Since dry cutting methods are used in two face milling processes and drilling oil holes processes, these three processes will generate small amounts of particulate matter; machining of hole systems and upper end face drilling is performed in machining centers or specialized machines designed according to product design with cutting fluid added during processing; thus pollutants generated include gray cast iron waste materials and waste cutting fluid.

1100, T26 travel box housing

This type of housing is made of HT200 material (gray cast iron). According to product structure, this company uses milling machines, CNC lathes, and specialized machines designed according to product design for processing. Since this production line uses dry cutting methods throughout, the main pollutants generated are gray cast iron waste materials and small amounts of particulate matter.

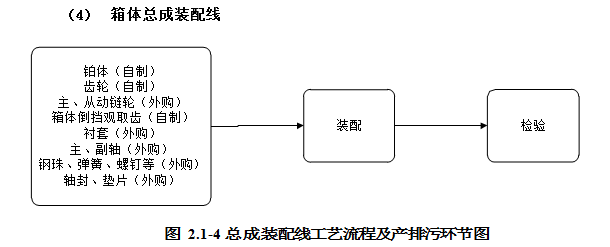

Process flow overview:

According to box structure and working principle, assemble various components of the transmission box according to relevant assembly processes. After assembly is complete, immerse the housing in water (completely submerged), then ventilate for 2~4 seconds to check for leaks. The water used for leak testing is tap water stored in an iron barrel for recycling without replacement; it is periodically replenished after consumption.

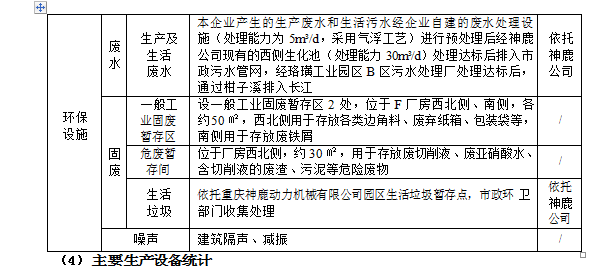

2.1.4 Generation and emission of pollutants

(1) Wastewater

The company's production wastewater is treated by its self-built integrated sewage treatment equipment before being discharged together with domestic sewage into Shenlu Company's biochemical pool.

(1) Production wastewater

The company's workshop mainly focuses on cleaning without generating cleaning wastewater. Production wastewater mainly comes from cleaning wastewater (about 0.33m³/d), handwashing wastewater (about 0.45m³/d), and cutting fluid wastewater (about 0.02m³/d). After treatment by integrated sewage treatment equipment with a capacity of 5m³/d, it is discharged together with domestic sewage into Shenlu Company's biochemical pool with a treatment capacity of 30m³/d after reaching Class III standards according to "Comprehensive Discharge Standard for Wastewater" (GB8978-1996), then through Ganzi Creek into the Yangtze River.

(2) Domestic sewage

This enterprise relies on the cafeteria of Shenlu Company and has not set up accommodation. Domestic sewage (approximately 1.35m³/d) comes from the factory toilets. The generated domestic sewage is treated together with production wastewater (after treatment by integrated wastewater treatment equipment) in the biochemical pool on the west side of Shenlu Company, which has a treatment capacity of 30m³/d, to meet the Class III standard of the "Comprehensive Discharge Standard for Wastewater" (GB8978-1996) before being discharged into the sewage treatment plant in Area B of Luohuang Industrial Park.

(GB18918-2002) Class I B standard, and then discharged into the Yangtze River through Ganzi Creek.

(2) Solid waste

The solid waste generated by this enterprise mainly includes: iron shavings, sodium nitrite-containing waste residue, waste containing cutting fluid, waste cutting fluid, gray cast iron waste, waste blades, waste drill bits, waste oil barrels, waste oil-soaked cotton yarn, waste oil-soaked gloves, discarded packaging, and domestic garbage.

① General industrial solid waste

The general solid waste temporary storage area has rain protection measures.

Iron shavings: In processes such as milling teeth, gear hobbing, slotting, tooth surface chamfering, and honing inner holes, the equipment requires continuous addition of regenerated hydraulic oil to wash the workpieces during operation to achieve lubrication and remove iron shavings generated during processing. According to information provided by the owner, the amount of oily iron shavings generated is approximately 33t/a. This project uses a degreasing machine to treat oily iron shavings; after degreasing, the amount of iron shavings is about 25.5t/a, and the regenerated oil produced is about 7.5t/a. The degreased iron shavings are collected and temporarily stored in the general solid waste storage area before being sold externally; regenerated oil is reused in production.

Gray cast iron waste: Various box bodies in this project generate gray cast iron waste during milling, turning, drilling, boring, etc. According to information provided by the owner, this part of the waste is generated at approximately 50t/a. After collection, it is stored in the general solid waste storage area and periodically sold for disposal.

Discarded blades and drill bits: Approximately 0.2t/a, collected and sold externally.

Discarded packaging: A small amount of waste packaging is generated during material receipt and packaging processes, approximately 0.2t/a, collected and sold externally.

售。

② Employee domestic garbage

The domestic garbage generated by employees is calculated at 1kg/person.d; thus, the total domestic garbage generation is 29.7t/a and is collected and processed by sanitation departments.

Unified collection and processing by the environmental sanitation department.

The domestic garbage from this project relies on the domestic garbage collection point of Shenlu Company. The garbage bin is located next to the car shed on the left side of the main gate.

③ Hazardous waste

The hazardous waste temporary storage area for this project has been equipped with comprehensive protective measures.

Sodium nitrite-containing waste residue: In this project’s grinding processes (for shafts and bevel gears), sodium nitrite mixed with water is used for lubrication and rust prevention. Sodium nitrite solution needs to be replenished daily after consumption; the replenishment amount is approximately 10kg/d. Wastewater is recycled without discharge. This project collects wastewater approximately every half month; about 0.12t/a of sodium nitrite-containing waste residue is collected and stored in the hazardous waste temporary storage area for disposal by Chongqing Yunqing Environmental Technology Co., Ltd.

Waste cutting fluid: In this project’s machining center for processing end faces, bottom surfaces, four-axis operations, hole systems, and drilling processes, cutting fluid is used. The cutting fluid is diluted at a ratio of 1:20 with water; it consumes about 0.17t monthly or about 6t/a with a water usage of approximately 40.8t/a. The diluted cutting fluid in machine tools is replaced once a year; its generation amount is about 6.5t/a and disposed of by Chongqing Yunqing Environmental Technology Co., Ltd.

Cutting residue: The generation amount is approximately 0.5t/a and disposed of by Chongqing Yunqing Environmental Technology Co., Ltd. Waste oil barrels: About 12 units/a or approximately 0.12t/a are disposed of by Chongqing Yunqing Environmental Technology Co., Ltd.

Waste oil-soaked cotton yarn and gloves: Approximately 0.3t/a are included in the hazardous waste exemption list; after collection, they are mixed with domestic garbage for unified disposal by sanitation departments.

Waste oil: Recovered from the factory area for recycling.

Sewage treatment plant sludge: Approximately 6t/a disposed of by Chongqing Yunqing Environmental Technology Co., Ltd.

Since the enterprise began operations, hazardous waste generation has been minimal; it has not yet been handed over to Chongqing Yunqing Environmental Technology Co., Ltd for collection and disposal but is temporarily stored in the hazardous waste storage area with a storage period not exceeding one year.

The enterprise leases part of Workshop F and Workshop E from Chongqing Shenlu Power Machinery Co., Ltd for construction and production purposes. Workshops E and F are located on the left side of Shenlu factory's main gate with two buildings arranged at right angles. Workshop E is roughly rectangular, about 100m long from north to south and about 28m wide from east to west; this enterprise rents about 1400m² on the west side of Workshop E mainly for a box assembly line and storage for raw parts and finished products; Workshop F has a trapezoidal layout covering an area of about 2500m² designated as the main production workshop with three production lines laid out; an office building located directly in front at the right angle where Workshops E and F connect covers about 300 m² over two floors.

2.1.5 Plane Layout

The enterprise has an oil storage facility located in the northwest corner of the factory area; both hazardous waste temporary storage area and sewage treatment facilities are on the west side of the factory area. In case of sudden environmental incidents, risks may primarily exist on the west side of the factory area.

The production wastewater from this enterprise undergoes pretreatment through a self-built wastewater treatment facility with a capacity of 5m³/d before being combined with employees' daily domestic sewage into Shenlu Company's biochemical pool on its west side.

Our company's production wastewater is pre treated by a set of self built sewage treatment equipment with a treatment capacity of 5m3/d, and then enters the biochemical tank on the west side of Shenlu Company together with the daily domestic sewage of employees.

The location plan of the factory area is shown in Figure 3.

2.1.6 Public works

(1) Water supply

The water supply for the enterprise is directly provided by the pipeline network of Chongqing Shenlu Power Machinery Co., Ltd. The outdoor pipeline network is laid in a circular manner, which can meet the needs of the enterprise.

(2) Drainage

Adopting a rainwater and sewage separation system. The rainwater discharge relies on the existing rainwater pipe network of Chongqing Shenlu Power Machinery Co., Ltd. Domestic sewage is treated by the existing biochemical tank of Chongqing Shenlu Power Machinery Co., Ltd. and discharged into the municipal sewage pipe network after meeting the standards. After being treated by the sewage treatment plant in Zone B of Luohuang Industrial Park and meeting the standards, it is discharged into the Yangtze River through Ganzi River.

The location plan of the factory area is shown in Figure 3.

2.1.6 Public works

(1) Water supply

The water supply for the enterprise is directly provided by the pipeline network of Chongqing Shenlu Power Machinery Co., Ltd. The outdoor pipeline network is laid in a circular manner, which can meet the needs of the enterprise.

(2) Drainage

Adopting a rainwater and sewage separation system. The rainwater discharge relies on the existing rainwater pipe network of Chongqing Shenlu Power Machinery Co., Ltd. Domestic sewage is treated by the existing biochemical tank of Chongqing Shenlu Power Machinery Co., Ltd. and discharged into the municipal sewage pipe network after meeting the standards. After being treated by the sewage treatment plant in Zone B of Luohuang Industrial Park and meeting the standards, it is discharged into the Yangtze River through Ganzi River.

(3) Power supply

Relying on the power supply network provided by Chongqing Shenlu Power Machinery Co., Ltd., a 10/0.4kV substation and a backup diesel generator room have been set up within Chongqing Shenlu Power Machinery Co., Ltd. to meet the electricity needs for production and daily life.

2.2 Geographic location and surrounding environment

2.2.1 Geographic location

2.2.1 Geographic location

Jiangjin District is located between 105°49′ to 106°38′ east longitude and 28°28′ to 29°28′ north latitude, with a width of 80 kilometers from east to west and a length of 100 kilometers from north to south, situated in the southwestern part of the centrally administered municipality of Chongqing. It is 50 kilometers by road from Yuzhong District; the railway distance is 65 kilometers; and the waterway distance is 72 kilometers.

It borders Banan and Qijiang to the east, Guizhou's Xishui to the south, Yongchuan and Sichuan's Hejiang to the west, and Bishan to the north. The transportation within the district is convenient, with the Yuyong and Yuchuan railways surrounding the city, and a well-connected road network, making transportation easy with complete municipal infrastructure.

Our company is located in Area B of Luohuang Industrial Park in Jiangjin District, Chongqing. The location has convenient transportation, with Jindong Road adjacent to the right side of the factory area, providing excellent geographical conditions.

The geographical location is shown in Appendix 1.

2.2.2 Natural Environment

(1) Geology, landform, geology

The overall terrain of Jiangjin District is higher in the south and lower in the north, mainly characterized by hilly and low mountainous landforms, divided into flat terraces, hilly areas, and mountainous regions, with hills accounting for 78.2% and low mountains accounting for 21.8%. The southern part features a trapezoidal area transitioning from the Yungui Plateau to the Sichuan Basin, while the northern part connects to Huagai Mountain and other branches of Huaying Mountain. The highest elevation is at Wugongba in Simian Mountain at 1709.4m, while the lowest point is at Zhongba in Luohuang Town at 178.5m, resulting in a relative height difference of 1530.9m.

Luohuang Town is located in a low mountainous hilly area extending southwest from Liangshan in the Huaying Mountain range. The northwest part is cut by Ganzi Creek into Mao'er Gorge, extending from Jianshan to Siligou along the eastern back slope of Guanyin Gorge. From northeast to southeast, it extends from Shijia Creek to Daqiao Village along Jinyin Gorge and Yunzhuan Mountain sloping westward. Therefore, the terrain of 'two mountains enclosing one valley' is evident, forming a valley with a tail in between. The landscape mainly consists of ridge slopes, shallow hills, and wide valleys with some areas featuring medium hills and valleys. There are many arable lands on mountain back slopes. The southeastern part consists of two valleys with an uplifted terrain in between; it is higher in the northeast and lower in the southwest, forming a boat-shaped middle-wide valley. The entire town has an elevation of about 330m. The highest point is Chaqi Mountain at an elevation of 554.0m, while the lowest point is Shijia Creek at an elevation of 170.8m.

The area where the enterprise is located features hilly gentle slopes; sloped areas are relatively high and flat with minor topographical fluctuations overall being higher in the southeast and lower in the northwest. No adverse geological phenomena such as landslides, dangerous rocks, collapses, or mudslides have been observed within the project scope; sloped edges and riverbanks are stable as they belong to stable sites where foundational bearing layers consist of mudstone and sandstone that are buried relatively shallowly with stable distribution for construction's seismic resistance.

(2) Climate and meteorological conditions

Jiangjin District has a subtropical climate that is warm and humid with abundant rainfall. It features warm winters and early springs, hot summers and cool autumns, continuous autumn rains, and a long frost-free period. The average annual temperature ranges from 16.5℃ to 18.5℃ with an extreme minimum temperature of -3.1℃. Summer lasts over four months with frequent high-temperature weather during midsummer; droughts occur prominently every eight years on average during July-August when average temperatures range from 26℃ to 30℃ with a maximum temperature reaching 44.5℃ (on August 16, 2006). The average annual rainfall is 1163.3mm with a historical maximum annual rainfall of 1357.7mm and a minimum annual rainfall of 740.10mm; average maximum daily rainfall over many years is recorded at 93.9mm with a maximum daily rainfall of 256mm (on July 17, 2007). Rainfall concentrates between May and September each year accounting for about 70% of annual precipitation with heavy rains occurring frequently in July and August. The average annual wind speed is recorded at 1.3m/s with a maximum wind speed (10-minute average) reaching up to 26.7m/s (on May 10,1958), measured extreme wind speed at 27.0m/s (on August 4,1961), maximum calm wind frequency at 7% (in January), average wind speed at 3.4m/s.

(3) Hydrological characteristics

The water system in the town where the enterprise is located flows into the Yangtze River basin. The Yangtze River flows eastward through Baisha entering within town limits at Caoguan Creek; along its banks are four administrative villages: Yanba, Wutai, Longhua Temple, and Shuangxi with a riverbank length of about 18km. Major place names along the riverbank include: Yanba, Zhongtangfang, Yangxikou, Jigong Beach, Wutaishan, Yazitou, Xiatanzi, Maliutuo, Taozixi, Shaxi Riverbank, Longmen Beach where it converges with Luojing River and Yutang Creek; Zhujiatan and Daqingdang converge into Leshi Creek flowing northeast towards Dingjiatuo before exiting through Shuangxuanzai.

The enterprise is located in Jian Mountain Village Group in Minshan Village of Luohuang Town; domestic sewage from the enterprise discharges into Ganzi Creek which ultimately flows into the Yangtze River. Ganzi Creek originates from Qilongxing in Heping Community of Luohuang Town; it traverses through central town area winding for about 40km with a riverbed width ranging from 5 to10m before merging into Yangtze River; most small streams within Luohuang Town flow into Ganzi Creek.

(According to Notice No.[2012]4 issued by Chongqing Municipal People's Government regarding adjustments to surface water environmental function categories) as well as Notice No.[2012]53 issued by Jiangjin District People's Government Office regarding adjustments to surface water environmental function categories state that Ganzi Creek belongs to Class III water bodies whose water quality complies with Class III standards set forth by 'Surface Water Environmental Quality Standards' (GB3838-2002).

(4) Biodiversity

Jiangjin District lies within subtropical evergreen broadleaf forest region of Eastern Sichuan Basin where natural vegetation consists of evergreen broadleaf forests, Masson pine forests, cypress forests, bamboo etc., allowing for year-round cultivation of crops; major field crops can be grown twice or five times over two years.

There are no nature reserves or high-level health resorts or scenic spots within the area where this enterprise is located.

No rare animals or plants have been found.

(5) Ecological environment

The natural conditions in Jiangjin District are complex, with rich vegetation layers and a wide variety of species. There are 8 types of naturally growing forest vegetation. Vascular plants include 198 families, 776 genera, and over 4000 species. The district has unique plants: there are more than 1500 species of microvascular plants, and precious species such as the Chinese double fan fern, tulip tree, sunflower pine, and Fujian cypress are known as "living fossils" and praised by UN experts as a "rare species gene pool." Jiangjin is rich in resources, with food crops including rice, wheat, barley, sorghum, sweet potato (red yam), corn (maize), potato (洋芋), mung bean, soybean, pea, chickpea, and kidney bean. Economic crops mainly include rapeseed, peanuts, sesame, tea leaves, silkworm cocoons, hemp, sugarcane, and tobacco leaves. The resource varieties of economic forest trees and fruit trees include 19 families, 25 genera, and 41 species, with citrus being the most famous. There are more than 10 types of minerals with rich reserves including natural gas, gypsum, quartz sand, quartz stone, limestone, and mineral water. The current forest area in the city is 1.18 million acres with a living wood stock of 3.5 million cubic meters and a forest coverage rate of over 27.5%.

The hydropower resources amount to over 200 thousand kilowatts.

More than 200 thousand kilowatts.

2.2.3 Environmental functional zones

(1) Surface water environment

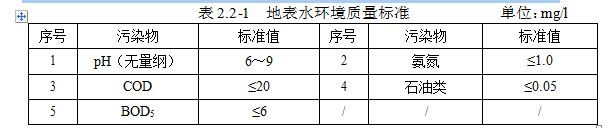

The receiving water body for the enterprise's wastewater is Ganzi Creek, which ultimately discharges into the Yangtze River. According to the "Notice on the Adjustment Plan for Surface Water Environmental Function Categories by the Chongqing Municipal People's Government" (Yufu Fa [2012] No. 4), the surface water receiving body Ganzi Creek has not undergone functional zoning; currently, the water quality of Ganzi Creek is relatively good. Additionally, based on recommendations in the "Environmental Impact Report of the Conceptual Planning for the Luohuang Group in Jiang District" of Chongqing: Ganzi Creek is suitable for function category III and is managed according to the "Surface Water Environmental Quality Standards" (GB3838-2002) for category III water bodies. The standard values are shown in Table 2.2-1.

(2) Groundwater

The enterprise belongs to the mechanical parts manufacturing category; according to Appendix A of the "Technical Guidelines for Environmental Impact Assessment Groundwater Standards," this enterprise is classified as groundwater category IV.

(3) Ambient air

According to the "Regulations on Environmental Air Quality Functional Zoning in Chongqing" (Yufu Fa [2016] No. 19), the location of this enterprise falls within an ambient air functional category II area.

(4) Sound environment quality standards

This enterprise is located in Area B of Luohuang Industrial Park; according to the "Technical Specifications for Sound Environment Functional Zoning"

(GB/T15190-2014), the area where the enterprise is located belongs to a category III sound environment functional area as per the "Sound Environment Quality Standards" (GB3096-2008), implementing category III standards from the "Sound Environment Quality Standards" (GB3096-2008).

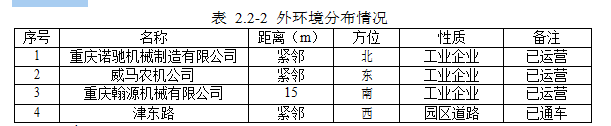

2.2.4 External environment of the enterprise

This enterprise is located in Area B of Luohuang Town Industrial Park in Jiangjin District of Chongqing City, renting factory space from Chongqing Shenlu Power Machinery Co., Ltd. The west side of this enterprise is adjacent to Luohuang Jindong Road; to the north is Chongqing Nuochi Machinery Manufacturing Co., Ltd.; to the south is Chongqing Hanyuan Machinery Co., Ltd.; and to the east is Weima Agricultural Machinery Company. There are no sensitive areas such as nature reserves or cultural relics facilities, scenic spots, or forest parks within the evaluation scope of this enterprise; environmental sensitive points mainly include scattered residential points nearby, schools, and residential areas. Within a radius of 500m from this enterprise, mechanical manufacturing enterprises are predominant with no residential points or environmental sensitive points related to food or medicine; it does not fall within health protection distances for food or medicine-related environmental sensitive points and has good compatibility with surrounding environments.

2.3 Environmental Risk Identification

2.3.1 Substances involving environmental risks

2.3.1 Substances involving environmental risks

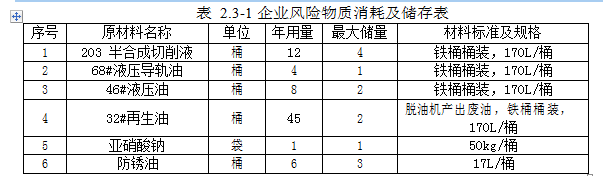

The main materials used during the production process of this enterprise include intermediate products and final products; based on the "Catalog of Hazardous Chemicals" (2015 edition) and considering their inherent hazards and toxicological indicators along with toxicity levels classification while taking into account their combustibility and explosiveness for identification. The main hazardous substances in this enterprise include guide rail oil, rust-proof oil, cutting fluid, and sodium nitrite.

The guide rail oil, hydraulic oil, recycled oil, rust-proof oil used during production processing are non-hazardous substances; sodium nitrite is a hazardous chemical with CAS number: 7632-00-0. Under normal usage conditions after certain controls and treatments before discharge, its impact on surrounding environments and human health can be controlled within acceptable limits; however, if leakage or failure of treatment measures occurs during accidents, there exists a possibility of fire hazards, explosions or poisoning. The physicochemical properties and hazards of environmental hazardous substances are shown in the table below:

2.3.2 Identification of environmental risks in the production process

Guide rail oil, recycled oil, hydraulic oil etc., are used for lubricating mechanical equipment; potential risks may arise from occurrences such as running out or leaking oils during production processes. However, most workshop equipment has oil collection trays which minimize external impacts. The production process does not involve high temperature or high pressure situations.

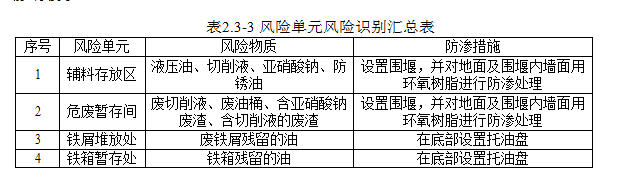

2.3.3 Identification of environmental risks during storage process

(1) Auxiliary material storage area

An auxiliary material storage area is set up on the northeast side of Workshop F covering an area of about 30m2 for storing hydraulic oil, cutting fluid, sodium nitrite, rust-proof oil etc., with a maximum volume of 170kg/barrel. If chemical barrels stored here break or tip over it could pollute water environments and soil environments.

(2) Hazardous waste temporary storage room

A hazardous waste temporary storage room is set up on the northwest side of Factory F covering an area of about 20m2 for temporarily storing waste cutting fluid produced during production processes along with waste oil barrels containing sodium nitrite waste residues and waste residues containing cutting fluid etc. If leakage occurs it could pollute water environments and soil environments.

(3) Iron shavings storage area

During product manufacturing processes waste iron shavings are generated; however these waste iron shavings have an oily surface which could pollute water environments and soil environments if stored without anti-seepage measures. Nevertheless after two rounds of de-oiling they are stored in trays which minimizes external environmental impacts.

(4) Iron box temporary storage area

During product manufacturing processes products obtained are stored in iron boxes; due to oily surfaces if stored without anti-seepage measures it could pollute water environments and soil environments. However all iron boxes in the factory area are stored on trays which minimizes external environmental impacts.

Environment, risk, enterprise, event, emergency, processing, production, limited company

3.4.2 Diffusion Pathways of Risk Substances in Water Environment Under abnormal circumstances

2019-11-20

There are risks of leakage and fire during the transportation of raw materials such as guide rail oil

2019-11-20